- 21

- Jul

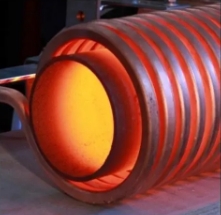

Induction heating self-tempering quality inspection self-tempering

Induction heating self-tempering quality inspection self-tempering

1) The results of self-tempering are shown in:

① Decrease of quenching hardness;

②The degree of internal stress relief.

2) The result of self-tempering depends on:

①The highest value of tempering temperature;

② Self-tempering time.

The part stays in the air from the completion of cooling until it is soaked again (if the subsequent process needs to be processed in time), the time sufficient to complete the tempering effect is called the self-tempering time. This time should be implemented in accordance with the regulations of the process card. The shorter the cooling time of the part, the more residual heat in the core of the part when other conditions are the same, the higher the self-tempering temperature, the more thorough the internal stress is eliminated, and the more the quenching hardness is reduced.

3) Inspection of self-tempering quality:

① Measure how much the hardness of the quenching is reduced, and compare the self-tempered parts after quenching with the parts that have not been self-tempered (cold through during quenching), and the value of the reduced hardness of the parts due to self-tempering can be obtained;

②Check for quenching cracks;

③Spray the surface of the part with a knife knife, and observe the tempering color (oxidation color) of the surface to roughly determine the self-tempering temperature;

④It is the most reliable to directly measure the self-tempering temperature with an infrared thermometer.