- 19

- Aug

Quenching machine model introduction

Quenching machine model introduction

1. Horizontal type, barrel type, mainly used for high-frequency quenching processing of automatic loading and unloading of optical shafts, such as: printer shafts, various piston rods, automobile gear levers, various precision hardware optical shafts, etc.

2. Manipulator type, vertical quenching machine tool, mainly used for vertical high-frequency quenching processing of shafts with steps, such as: motors, spline shafts, machine tool spindles, automobile rotating shafts, etc., workpieces that need vertical high-frequency quenching .

Application range:

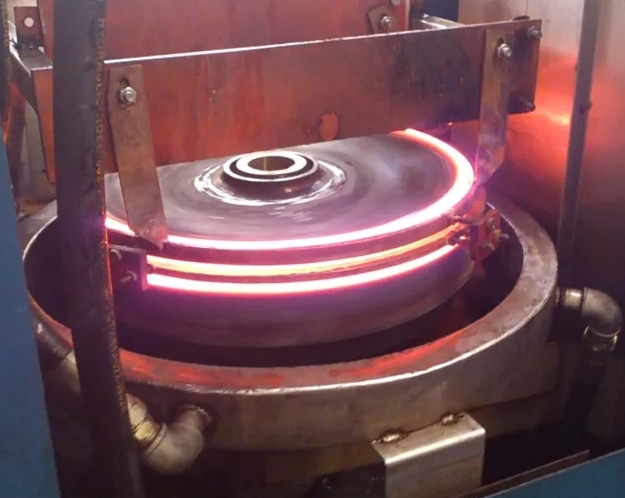

High-frequency quenching machine is suitable for quenching and tempering of various workpieces, such as induction quenching of shafts, gears, guide rails, discs, pins, etc. Simultaneous quenching and other functions; CNC system or PLC and frequency conversion speed control system are used to realize workpiece positioning and scanning, and PLC is connected with induction power supply to realize fully automatic production.

Vertical (quenching of shaft parts) + horizontal (quenching of ring gear parts).

Compared with the ordinary quenching machine and the automatic high-frequency quenching machine, the function or operation of the automatic high-frequency quenching machine should be advanced, and it can save energy and improve a lot of output.