- 29

- Aug

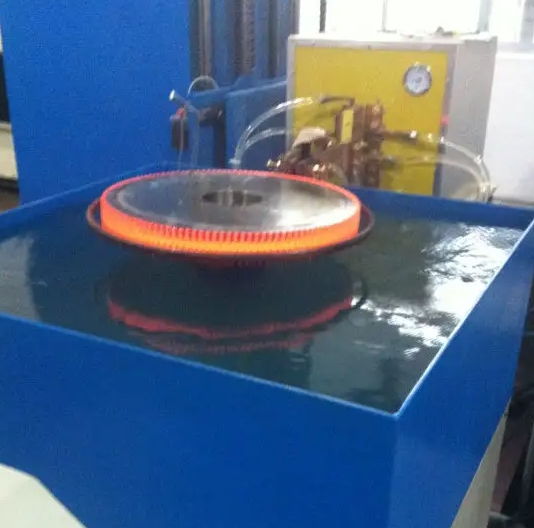

What are the advantages of high frequency quenching

What are the advantages of high frequency quenching

The application of induction heating surface quenching has the following advantages compared with ordinary heating and quenching:

1. The heating speed is extremely fast, which can expand the transformation temperature range of the A body and shorten the transformation time.

2. After quenching, the surface layer of the workpiece can get extremely fine cryptocrystalline martensite, and the hardness is slightly higher (2-3HRC). Lower brittleness and higher fatigue strength.

3. The workpieces treated by this process are not easy to be oxidized and decarburized, and even some workpieces can be directly assembled and used after treatment.

4. The hardened layer is deep, easy to control and operate, easy to realize mechanization and automation.

5. Flame surface heating and quenching