- 19

- Oct

Vertical, sequential induction heating furnace

Vertical, sequential induction heating furnace

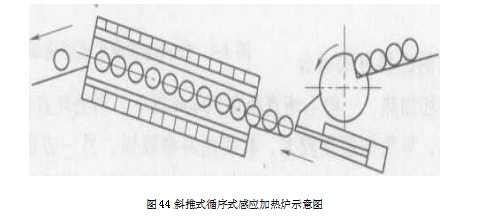

The picture shows a schematic diagram of a vertical and sequential induction heating furnace. After the blank is pushed to the lower part of the inductor, the ejector device rises to send the blank into the inductor, and the blank is supported by the support block at the lower part of the inductor. When a cold blank is fed into the lower part of the inductor, a hot blank that has been heated to reach the temperature requirement is pushed out from the upper part of the inductor, that is, one feeding and discharging are completed according to the production cycle. The inductor is continuously powered during the heating process. This induction heating method is suitable for heating blanks with larger diameters and short lengths, such as round cakes and slabs. The advantage is that the inductor of this kind of induction heating method does not bear the quality of the blank, the guide rail only plays a guiding role, and the service life is longer.