- 03

- Sep

Industrial chiller

Industrial chiller

A. Chiller composition:

The chiller includes four main components: compressor, evaporator, condenser, and expansion valve

B. The cooling principle of the chiller

The operation of the chiller system is through three interrelated systems: refrigerant circulation system, water circulation system, and electrical automatic control system

C. Chiller refrigerant circulation system

The liquid refrigerant in the evaporator absorbs the heat in the water and starts to evaporate. Eventually, a certain temperature difference is formed between the refrigerant and the water. The liquid refrigerant is also completely evaporated and becomes gaseous and then sucked by the compressor and compressed (pressure and temperature increase) , The gaseous refrigerant absorbs heat through the condenser (air-cooled/water-cooled), condenses into a liquid, and is throttled by a thermal expansion valve (or capillary tube) to become a low-temperature and low-pressure refrigerant to enter the evaporator, completing the refrigerant cycle process.

D. Electrical automatic control system

The electrical automatic control system includes a power supply part and an automatic control part; the power supply part supplies power to compressors, fans, water pumps, etc. through the contactor; the automatic control part includes a combination of thermostat, pressure protection, delayer, relay, overload protection, etc. Achieve automatic start and stop according to water temperature, protection and other functions.

E. Air-cooled chiller cooling method

The air-cooled chiller adopts the air cooling method, eliminating the need for cooling water towers, circulating water pumps and piping systems that are essential for cooling water systems, avoiding condenser scaling and water pipe blockage in areas with poor water quality, and also saving water resources. It is the most economical and simple water chiller to maintain and repair among the current cold water air-conditioning equipment products. Air-cooled chillers have a higher one-time investment than water-cooled chillers, but the annual operating cost is lower than that of water-cooled chillers. In addition, air-cooled chillers are noisy and the heat emitted is directly radiated at the place where the chiller is installed. Therefore, there are requirements for the ambient temperature of operation, and it can only be installed outdoors.

F. Features of air-cooled chiller:

1. No installation of cooling tower, easy to install and convenient to move, suitable for occasions where water source is lacking and no installation of water tower is required. 2. Low noise fan motor, excellent cooling and condensation effect, stable throttling mechanism, and excellent anti-rust treatment. 3. Adopt high-performance compressor imported from Europe and America, high EER value, low noise, stable operation

The working principle of the air-cooled chiller: The air-cooled chiller uses a shell and tube evaporator to exchange heat between water and refrigerant. The refrigerant system absorbs the heat load of the water and cools the water to produce cold water. The heat is carried by the compressor. To finned cooler

Yes, it will be lost to the outside air by the cooling fan (wind cooling D)

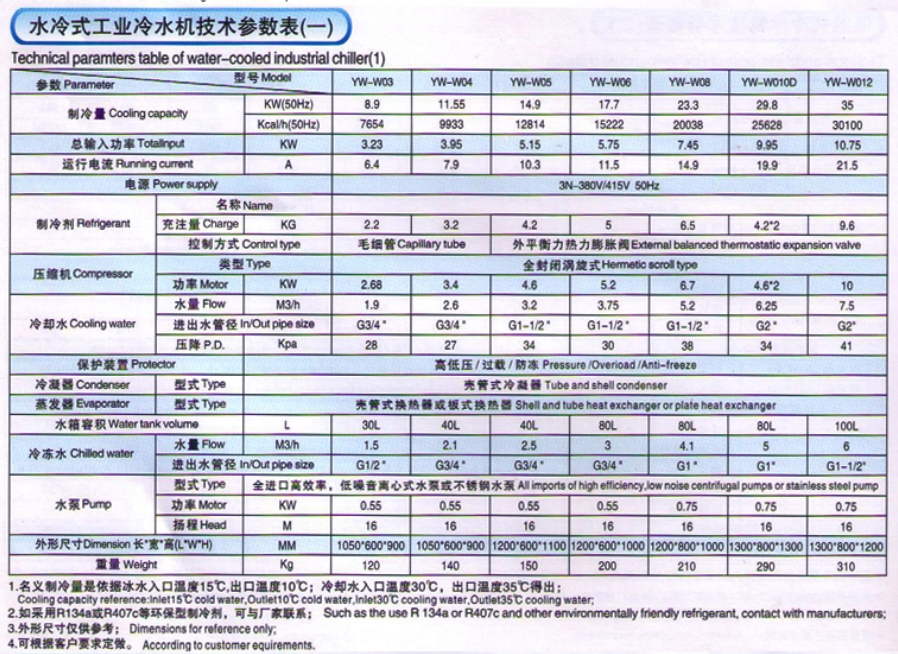

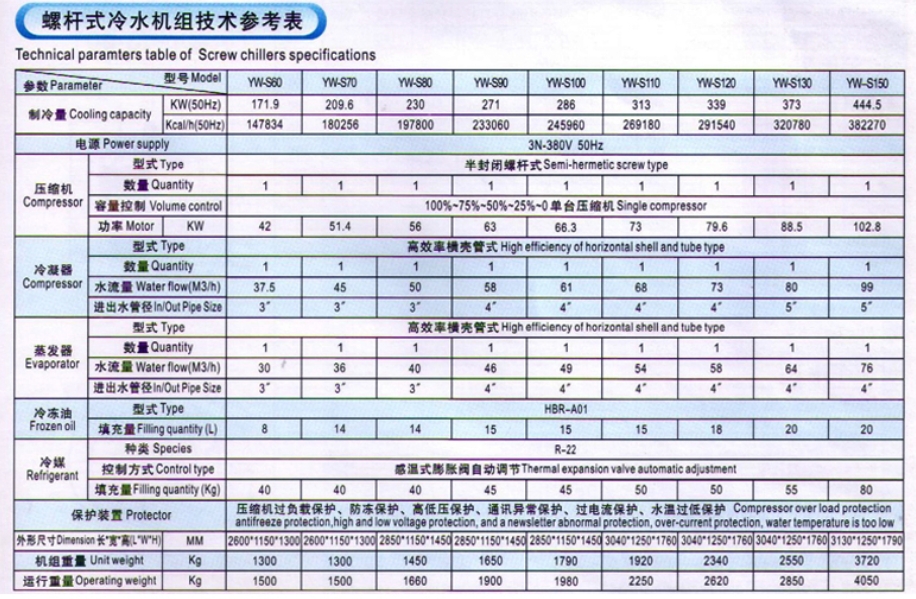

G. Industrial chiller technical parameters, product support customization, please contact us.