- 15

- Sep

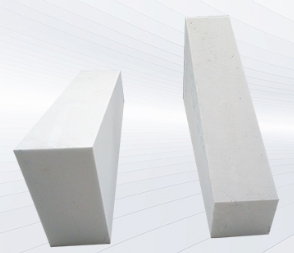

Corundum mullite brick

Corundum mullite brick

Product advantages: high temperature resistance, corrosion resistance, oxidation resistance, good thermal stability, and low linear change rate.

Product application: Mainly used in petrochemical industry, large and medium-sized synthetic ammonia gasifier and magnetic material gas furnace materials, high-temperature industrial kiln supporting facilities materials, etc.

product description

Corundum and mullite bricks are made of high-purity corundum and mullite as raw materials, shaped by high pressure and fired at high temperature. The product has the characteristics of high temperature resistance, corrosion resistance, oxidation resistance, good thermal stability, and low linear change rate.

Description of corundum mullite bricks:

1. Heavy materials have good compactness, high compressive strength, resistance to various corrosive gases, good thermal shock stability, excellent thermal conductivity, and wear resistance.

2. Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high service temperature and low thermal conductivity.

Physical and chemical indicators

| project | High purity corundum brick

DL-99 |

Corundum mullite brickDL-95 | Corundum mullite brickDL-90 | Corundum mullite brickDL-80 |

| AI2O3% ≥ | 99 | 95 | 90 | 80 |

| SiO2 %≤ | 0.3 | 3.0 | 9.0 | 18 |

| Fe2O3%≤ | 0.2 | 0.2 | 0.5 | 0.5 |

| R2O% ≤ | 0.3 | 0.6 | 0.6 | 0.4 |

| Bulk density/(g/cm³) | 3.0 | 2.9 | 2.85 | 2.7 |

| Compressive strength at room temperature/Mpa≥ | 75 | 100 | 100 | 60 |

| Refractoriness ℃ | 1790 | 1790 | 1790 | 1790 |

| Load softening start temperature 0.2Mpa ℃≥ | 1700 | 1700 | 1700 | 1650 |

| Reheating line change (1600℃×3h)% ≤ | 0.2 | 0.2 | 0.2 | 0.3 |

| Thermal stability times 1100℃ water cooling≥ | 6 | 10 | 10 | 20 |