- 17

- Sep

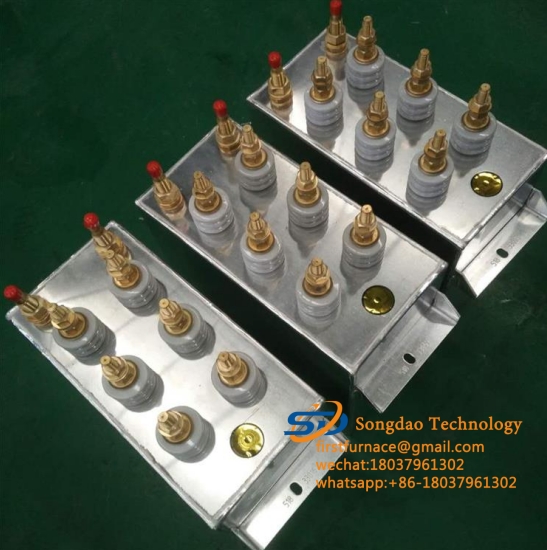

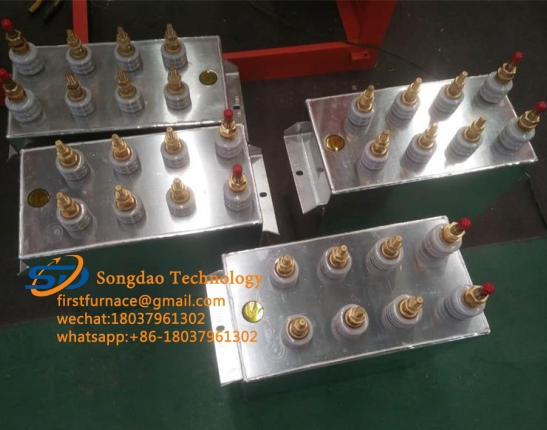

Induction melting furnace accessories: intermediate frequency capacitor

Induction melting furnace accessories: intermediate frequency capacitor

The electric heating capacitor is mainly composed of two parts: the shell and the heart.

The shell is a rectangular box with a sealed structure made by bending and welding aluminum plates. The cover is equipped with a silicon rubber sealed, porcelain sleeve-supported wiring guide and cooling water pipe interface; the two ends of the box are welded with brackets for transportation and installation. In addition to the heart, it is also filled with high-quality insulating oil-non-chlorinated biphenyl diarylethane.

The capacitor core is composed of components, insulators and cooling water pipes. The cooling water pipes and the component pole plates are directly welded into one body, which not only serves as a part of the electrode, but also serves as a heat-conducting carrier, which has a cooling effect.

The capacitor element is made of double-sided roughened polypropylene film as the medium, and the soft aluminum foil is a protruding foil element formed by winding and flattening the pole plate. For components with higher voltages, in order to improve the fringe electric field concentration, measures are taken to fold the aluminum foil.

Electric heating capacitors are mainly used in induction heating electrical systems with a frequency of 40 to 50000HZ to increase power factor or improve circuit characteristics. The performance of the electric heating capacitors supplied by our company fully meets the requirements of GB3984-83 “Electric Heating Capacitors” and IEC110 (1973) “Capacitors for Induction Heating Devices with Frequency 40~24000hz”.