- 05

- Sep

Method for selecting closed water cooling system of molten iron furnace

Method for selecting closed water cooling system of molten iron furnace

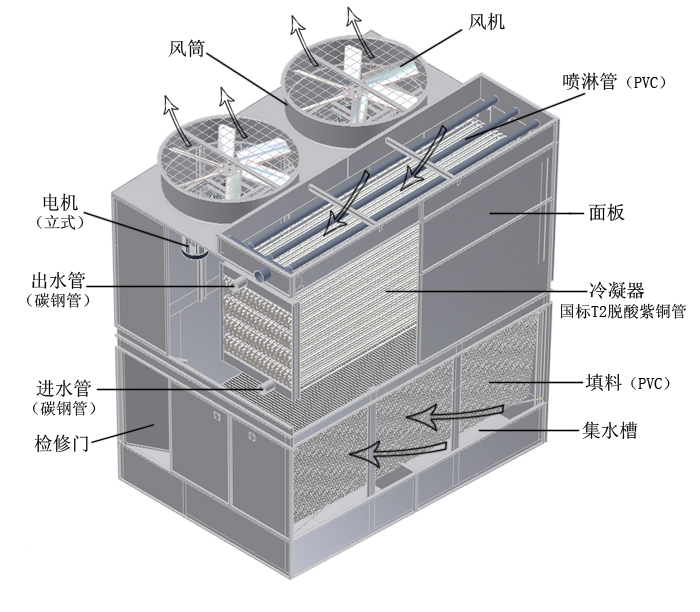

The wind-water cooling system is in the form of a closed cooling tower. The closed cooling system does not need to dig the pool, and the site needs only to connect the interface with the equipment to be cooled, without adding other auxiliary equipment. The whole set of circulating system water is soft water, the water quality is good, the scale is not scaled, the closed loop makes the water loss very small, and the equipment use and maintenance cost can be greatly reduced. Since the electric part and the furnace part have different requirements on the water temperature, that is, the heat temperature of the part of the furnace is between 35-55 ° C (the energy saving angle is relatively energy-saving), and the electric part requires the lower the water temperature. The lower the rate, it is recommended to use two sets of closed cooling towers to separate the electrical part and the furnace part.

Features of the fluid cooler :

1 FL series closed cooling tower is stylish and beautiful, with compact internal structure and reasonable layout;

2 The outer shell plate is made of 2mm thick hot-dip galvanized sheet (optional stainless steel plate), which is welded, folded and punched by CNC machine tool and assembled without weld seam. The size is accurate and flat;

3 cooler (main part) is made of international standard T 2 deacidified copper tube, with few solder joints and welded with silver electrode;

4 PVC high-efficiency dehydrator can make the water drift rate less than 0.001% , making it possible to place the equipment in water-sensitive areas;

5 PVC high efficiency style grille, small wind resistance, reduce the energy consumption of the fan and there will be no splashing of spray water, the sun will not reach the inside of the sink, effectively preventing the growth of algae;

6 The pumping station is composed of a main water pump and a backup water pump. When the main water pump fails, the standby water pump can be started immediately, making continuous water supply possible. In the event of a power outage, the gasoline engine emergency pump can be selected for the user to complete the continuous cooling of the induction coil;

Closed water cooling system schematic

7 fan blades are aluminum alloy, motor is aluminum shell three anti-motor, domestic famous brand;

8. circulating water tank is made of 304 stainless steel plate and has an imported liquid level alarm;

9. closed cooling tower is provided in the inlet pressure display, the power supply in the furnace is also provided with a pressure inlet at the display (installation site), the differential pressure read by the pressure drop of water, so as to achieve effective cooling, in order to ensure that the device Safe water flow range;

10. The closed cooling tower has a water temperature display and alarm function at the water outlet, and can control the temperature of the inlet and outlet water through the digital temperature controller to control the opening and closing of the spray system. The closed cooling tower is continuously and safely and efficiently cooled by the intermediate frequency power supply and the furnace body within a predetermined water temperature range.

The cooling circulating waterway in the intermediate frequency power supply cabinet and the compensation capacitor bank is connected by stainless steel pipes. The connection is reliable and the mark is obvious. It can withstand 1.5 times of the internal water design pressure without leakage.