- 28

- Feb

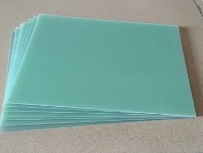

What are the use conditions of epoxy glass fiber board

What are the use conditions of epoxy glass fiber board

Epoxy glass fiber board is also epoxy phenolic laminated glass cloth board. Epoxy resin generally refers to organic polymer compounds containing two or more epoxy groups in the molecule. Except for a few, their relative molecular masses are all different. high. The molecular structure of epoxy resin is characterized by the active epoxy group in the molecular chain. The epoxy group can be located at the end, in the middle or in a cyclic structure of the molecular chain. Because the molecular structure contains active epoxy groups, they can undergo cross-linking reactions with various types of curing agents to form insoluble and infusible polymers with a three-way network structure. The epoxy glass fiber board of this product is made by heating and pressing with epoxy resin. It has high mechanical performance at medium temperature and stable electrical performance under high humidity. It is suitable for high-insulation structural parts for machinery, electrical appliances and electronics, with high mechanical and dielectric properties, good heat resistance and moisture resistance, and heat resistance class F (155 degrees).

There are many types of epoxy glass fiber board, the common ones are 3240, G11, G10, FR-4, etc. They have the same general performance, are all high-temperature insulation materials, and the details are slightly different. For example, the use temperature of FR-4 is Around 130°C, while the use temperature of G11 can reach 180°C. So how is the performance? In this article, I will talk about the use conditions of epoxy glass fiber board.

1. The operating temperature of epoxy glass fiber board is 120 degrees Celsius. It can be used in an environment of 130 degrees Celsius in a short time. If it exceeds this temperature, it will warp, crack and become unusable.

2. Има добри електрически свойства, с диелектрична якост от 1000V/MIL и напрежение на пробив от 65 kV, което може да работи непрекъснато в среда с високо напрежение и ток.

3. Има силна обработваемост, добра механична способност, якост на натиск от 303 MPa, якост на опън от 269 MPa, якост на огъване от 455 MPa и якост на срязване от 130 MPa. Той може да издържи на силни въздействия от външния свят и има добра здравина.

4. Химичните свойства също са добри, с известна степен на устойчивост на корозия.

5. Той е негорим, без бром, в съответствие със стандартите на ЕС, екологичен и няма да замърсява околната среда. В чужбина се използва повече.

От горното може да се види, че производителността на плочата от епоксидни стъклени влакна е много добра. Изработен е от лист от стъклени влакна, изтъкан с непрекъснати нишки, свързани с епоксидна смола. Може да се персонализира директно според изискванията на клиента. Ако обработените части са обработени, вижте Обработка на чертежи.