- 28

- Feb

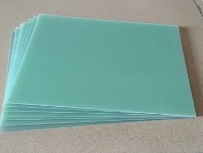

What are the use conditions of epoxy glass fiber board

What are the use conditions of epoxy glass fiber board

Epoxy glass fiber board is also epoxy phenolic laminated glass cloth board. Epoxy resin generally refers to organic polymer compounds containing two or more epoxy groups in the molecule. Except for a few, their relative molecular masses are all different. high. The molecular structure of epoxy resin is characterized by the active epoxy group in the molecular chain. The epoxy group can be located at the end, in the middle or in a cyclic structure of the molecular chain. Because the molecular structure contains active epoxy groups, they can undergo cross-linking reactions with various types of curing agents to form insoluble and infusible polymers with a three-way network structure. The epoxy glass fiber board of this product is made by heating and pressing with epoxy resin. It has high mechanical performance at medium temperature and stable electrical performance under high humidity. It is suitable for high-insulation structural parts for machinery, electrical appliances and electronics, with high mechanical and dielectric properties, good heat resistance and moisture resistance, and heat resistance class F (155 degrees).

There are many types of epoxy glass fiber board, the common ones are 3240, G11, G10, FR-4, etc. They have the same general performance, are all high-temperature insulation materials, and the details are slightly different. For example, the use temperature of FR-4 is Around 130°C, while the use temperature of G11 can reach 180°C. So how is the performance? In this article, I will talk about the use conditions of epoxy glass fiber board.

1. The operating temperature of epoxy glass fiber board is 120 degrees Celsius. It can be used in an environment of 130 degrees Celsius in a short time. If it exceeds this temperature, it will warp, crack and become unusable.

2. Are proprietăți electrice bune, cu o rezistență dielectrică de 1000V/MIL și o tensiune de rupere de 65 kV, care poate funcționa continuu într-un mediu de înaltă tensiune și curent.

3. Are o prelucrabilitate puternică, capacitate mecanică bună, rezistență la compresiune de 303 MPa, rezistență la tracțiune de 269 MPa, rezistență la încovoiere de 455 MPa și rezistență la forfecare de 130 MPa. Poate rezista la impacturi puternice din lumea exterioară și are o rezistență bună.

4. Proprietățile chimice sunt de asemenea bune, cu un anumit grad de rezistență la coroziune.

5. Este non-ignifug, non-brom, în conformitate cu standardele UE, prietenos cu mediul și nu va polua mediul. Este folosit mai mult în străinătate.

Din cele de mai sus se poate observa că performanța plăcii din fibră de sticlă epoxidica este foarte bună. Este realizat din foaie de fibră de sticlă țesută cu filamente continue lipite cu rășină epoxidică. Poate fi personalizat direct în funcție de cerințele clientului. Dacă piesele prelucrate sunt prelucrate, vă rugăm să consultați desenele Procesare.