- 11

- May

Five advantages of steel shell induction melting furnace

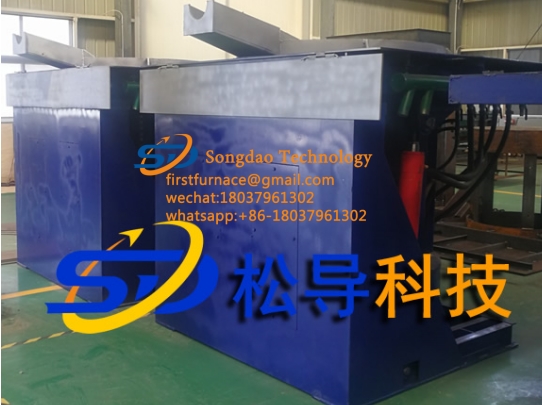

Five advantages of steel shell induction melting furnace:

First: The steel shell Induktionsschmelzofen is durable and beautiful, especially the large-capacity furnace body, which requires a strong rigid structure. From the safety point of view of the tilting furnace, use a steel shell furnace as much as possible.

Second: The yoke made of silicon steel sheet shields and emits the magnetic field lines generated by the induction coil, reduces magnetic flux leakage, improves thermal efficiency, increases output, and saves about 5%-8%.

Third: The presence of the steel shell induction melting furnace cover reduces the heat loss and improves the safety of the equipment.

Fourth: The steel shell induction melting furnace has a long service life, and aluminum is oxidized more severely at high temperatures, resulting in fatigue of the metal’s toughness. At the foundry site, it is often seen that the shell of the aluminum shell furnace that has been used for about one year is in bad condition, and the steel shell furnace has less magnetic flux leakage, and the service life of the equipment is much longer than that of the aluminum shell furnace.

Fifth: The safety performance of steel shell induction melting furnace The steel shell furnace is much better than the aluminum shell furnace. The aluminum shell is easily deformed due to high temperature and heavy pressure during melting, and the safety is poor. The steel shell furnace uses hydraulic tilting furnace, which is safe and reliable.