- 30

- Aug

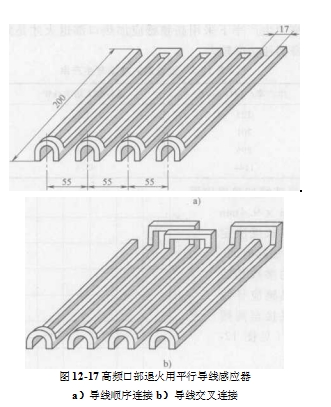

High frequency induction heating mouth annealing for small diameter steel pipes

Mitar girma shigar da dumama baki annealing for small diameter steel pipes

The small-diameter steel pipe undergoes cold work hardening after drawing. In order to close the mouth in the next process, the mouth of the small-diameter steel pipe must be recrystallized and annealed. The material of the small diameter steel pipe is low carbon steel, the wall thickness is 0.25 ~ 0.4mm, and the length of the annealing part is 10 ~ 14mm, so high-frequency current induction heating annealing is used. Compared with the previous use of resistance furnace for heating and annealing, the productivity is increased by more than 12 times, the power consumption is reduced by 60% -70%, the product quality is improved, and the rejection rate is reduced from 0.1% of the resistance furnace to 0.02%, and the operation is simple. , Working conditions have also been improved.

1. Heating time of high frequency induction heating mouth annealing

The time of sequential heating is determined by the length of the inductor and the speed at which the small diameter steel pipe passes through the inductor. Through the experiment, the heating time can get the same performance in the range of 6s, and it is 6 ~ 8s on the 8-row high frequency annealing machine.

2. The power consumption of high frequency induction heating mouth annealing

It is cost-effective to use high-frequency induction heating mouth annealing at a sufficiently high productivity. The reason is that the high-frequency generator itself consumes a lot of power.