- 30

- Sep

Automatic induction heating furnace

Automatic induction heating furnace

1. Application of automatic induction heating furnace:

The automatic induction heating furnace is mainly used for hot forging production lines and metal quenching and tempering heating production lines used in auto parts, and is mainly used for heating before forging of alloy steel and heat treatment and tempering heating of round steel.

2. Parameters of automatic induction heating furnace:

1. Materials heated by automatic induction heating furnace: alloy steel, stainless steel, carbon steel, etc.

2. The specifications of the round steel heated by the automatic induction heating furnace: diameter Φ25mm~Φ120mm; round steel length L<450mm

3. The ratio of length to diameter of round steel heated by automatic induction heating furnace: L/D≧1.5 L-D≧25mm

4. Heating power of automatic induction heating furnace: 160Kw~2500Kw 2~4KHz

5. Automatic feeding method of induction heating furnace: automatic stepped feeding

6. Automatic induction heating furnace control method: Siemens PLC control system

7. Cooling method of automatic induction heating furnace: HSBL cooling tower cooling system

8. The overall dimensions of the automatic induction heating furnace: 9500 mm long, 2800 mm wide and 2170 mm high

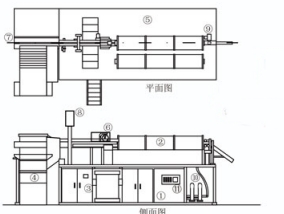

3. Schematic diagram of automatic induction heating furnace: