- 30

- Sep

Isithando sokushisa sokungeniswa okuzenzakalelayo

Isithando sokushisa sokungeniswa okuzenzakalelayo

1.Ukusetshenziswa kwesithando sokushisa sokungeniswa okuzenzakalelayo:

Isithando somlilo sokushisa esizenzekelayo sisetshenziselwa ikakhulukazi ukukhiqiza imigqa ekhiqizayo eshisayo kanye nokuqedwa kwensimbi nokushisa ukufudumeza komugqa okusetshenziswa ezingxenyeni zezimoto, futhi kusetshenziselwa ukufudumeza ngaphambi kokwenza i-alloy steel kanye nokwelashwa kokushisa nokushisa okushisa kwensimbi eyindilinga.

Amapharamitha wesithando sokushisa sokungeniswa okuzenzakalelayo:

1. Izinto ezishushubezwe ngesithando sokushisa sokungeniswa okuzenzakalelayo: i-alloy steel, insimbi engagqwali, i-carbon steel, njll.

2. Ukucaciswa kwensimbi eyindilinga efudunyezwe isithando somlilo esizenzekelayo sokushisa: ubukhulu Φ25mm ~ Φ120mm; insimbi round L < 450mm

3. Isilinganiso sobude nobubanzi bensimbi eyindilinga efudunyezwe ngomlilo othomathikhi wokungeniswa: L / D ≧ 1.5 LD ≧ 25mm

4.Ukushisa amandla esithandweni sokushisa sokungeniswa okuzenzakalelayo: 160Kw ~ 2500Kw 2 ~ 4KHz

5.Indlela yokudla okuzenzakalelayo yesithando sokufudumeza sokungeniswa: ukuphakelwa okuzenzakalelayo

6.Indlela yokulawula ukushisa kwesithando esizenzekelayo: Uhlelo lokulawula i-Siemens PLC

7.Indlela yokupholisa yesithando sokushisa sokungenisa esizenzekelayo: Uhlelo lokupholisa lombhoshongo we-HSBL

8. Ubukhulu obuphelele besithando sokushisa sokungeniswa okuzenzakalelayo: 9500 mm ubude, 2800 mm ububanzi no-2170 mm ukuphakama

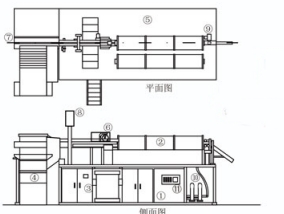

3. Umdwebo wesikimu wesithando sokushisa sokungeniswa okuzenzakalelayo: