- 31

- Oct

Electromagnetic crystallizer and its structure

Electromagnetic crystallizer and its structure

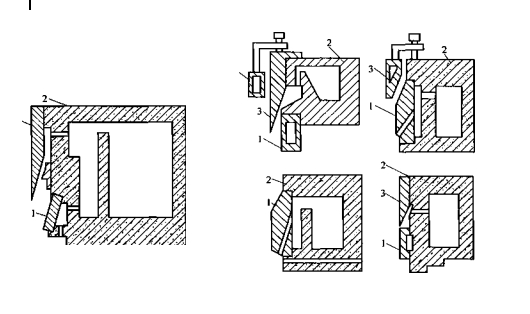

The electromagnetic crystallizer is composed of cooling water jacket, induction coil, shielding cover and other main components. At present, several typical electromagnetic crystallizer structures that have been used in industrial installations at home and abroad are shown in Figure 8-9 and Figure 8-10.

In electromagnetic casting, the flow plate is the channel through which the molten metal is introduced and distributed from the aluminum melting furnace to the electromagnetic crystallizer. The liquid flow control valve can ensure that the amount of liquid metal flowing into the electromagnetic crystallizer per unit time remains unchanged. The liquid flow control valve is placed in the float funnel. When the liquid metal flow rate increases, the metal liquid level in the electromagnetic crystallizer rises, and the liquid flow control valve rises and blocks the flow port of the flow plate, so that the flow rate of the liquid metal decreases. On the contrary, it can increase the flow of liquid metal. Maintaining the stability of the metal liquid level in the electromagnetic crystallizer in dynamic balance is the primary condition for the realization of electromagnetic casting in the process. Because only in this way can we ensure constant electromagnetic thrust and molten metal

Equilibrium conditions for stable column pressure.