- 30

- Dec

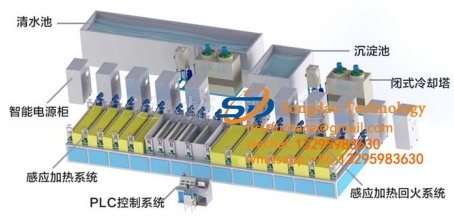

Steel phaj quenching thiab tempering ntau lawm kab

Steel phaj quenching thiab tempering ntau lawm kab

Khoom npe: steel phaj quenching thiab tempering ntau lawm kab

Cov khoom siv ua haujlwm: carbon hlau alloy steel, thiab lwm yam.

Haum rau thickness: ntau dua 5.0mm

Txheej txheem: cua sov, quenching

Qhov kub thiab txias: 900-950 ℃

Lub zog yuav tsum tau muaj: 100-8000 kW

Cov hlau phaj quenching thiab tempering ntau lawm kab txais yuav nruab nrab zaus induction cua sov fais fab mov tswj nta:

1. Parallel resonance tsim, theem hloov lub zog, lub zog loj, tsis tshua muaj kev sib haum xeeb, thiab kev ua haujlwm yooj yim.

2. Cov khoom siv hluav taws xob thiab cov inductor ib txwm ua kom ntseeg tau qhov sib txuam nrog lub zog tag nrho. Piv nrog rau cov tsoos fais fab inverter, nws tuaj yeem txuag hluav taws xob los ntawm 15-30%.

3. Cov khoom siv hluav taws xob tuaj yeem hloov kho qhov tsis ua haujlwm ntawm cov khoom sib txawv.

4. Kev tswj tag nrho lub vijtsam kov, kev teeb tsa digital ntshiab, ua tiav cov txheej txheem cov ntaub ntawv thiab qib kev tswj hwm nruj. Muaj lub Hoobkas pib dua.

5. Cov hlau phaj quenching thiab tempering ntau lawm kab muaj kev tiv thaiv tus kheej (overcurrent, overpressure, dej siab, theem poob, undervoltage, overload) system. Thaum muaj xwm txheej ceev, cov khoom siv muaj kev kuaj xyuas tus kheej.