- 30

- Dec

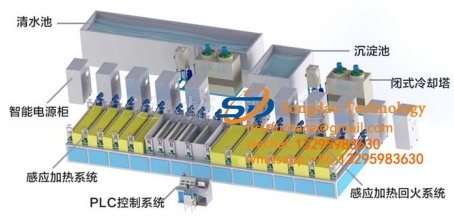

Steel plate quenching and tempering production line

Steel plate quenching and tempering production line

Product name: steel plate quenching and tempering production line

Workpiece material: carbon steel alloy steel, etc.

Suitable for thickness: greater than 5.0mm

Process: heating, quenching

Heating temperature: 900-950℃

Power requirement range: 100-8000 kilowatts

The steel plate quenching and tempering production line adopts intermediate frequency induction heating power supply control features:

1. Parallel resonance design, phase shift power, high power factor, low harmonics, and simple operation.

2. The power supply and the inductor always keep reliable matching with the full power output. Compared with the traditional power inverter, it can save energy by 15-30%.

3. The power supply can automatically adjust the parameters of workpieces of different sizes.

4. Full touch screen control, pure digital settings, complete process records and strict authority levels. Have a factory reset.

5. The steel plate quenching and tempering production line has a self-protection (overcurrent, overpressure, water pressure, phase loss, undervoltage, overload) system. In an emergency, the equipment has a self-diagnosis function.