- 19

- Jan

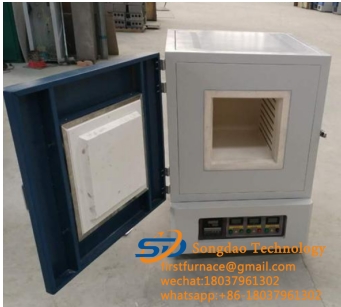

Taw qhia ntawm muffle furnace classification thiab Scope ntawm daim ntawv thov

Qhia txog ntawm muffle rauv classification thiab Scope ntawm daim ntawv thov

muffle furnace yog cov khoom siv cua sov ua haujlwm cyclically, uas tuaj yeem siv rau hauv cov chaw soj nstuam, cov chaw lag luam thiab cov mining thiab cov chaw tshawb fawb txog kev tshawb fawb thiab cov cua sov ntawm cov hlau me me hauv cov txheej txheem ntawm quenching, annealing thiab tempering. Nyob rau tib lub sijhawm, kev faib cov cub tawg tuaj yeem raug cais raws li lawv cov khoom cua sov, ntsuas kub, thiab cov tswj, raws li hauv qab no:

Raws li cov khoom cua sov, muaj xws li: hluav taws xob rauv hlau, silicon carbide pas nrig thiab silicon molybdenum pas nrig;

Raws li qhov ntsuas kub, nws feem ntau muab faib ua: 1000 ° C lossis tsawg dua, 1000 ° C, 1200 ° C, 1300 ° C, 1400 ° C, 1600 ° C, 1700 ° C, 1800 ° C muffle furnace.

Raws li tus maub los, muaj cov hauv qab no: cov lus taw qhia, cov lus pom zoo tib yam digital, PID hloov kho lub rooj, lub rooj tswj kev pab cuam; Raws li cov khoom siv rwb thaiv tsev, muaj ob hom: zoo tib yam refractory cib thiab ceramic fiber.

Tom qab nkag siab txog kev faib tawm ntawm muffle furnaces, peb yuav nkag siab txog qhov kev thov:

(1) Thermal processing me me workpieces, cement and building material industries.

(2) Kev lag luam kws tshuaj: tshuaj xyuas tshuaj, kev kho mob qauv ua ntej, thiab lwm yam.

(3) Analytical chemistry: ua piv txwv hauv kev tsom xam dej zoo thiab kev txheeb xyuas ib puag ncig. Lub qhov cub muffle kuj tseem siv tau rau cov roj av thiab nws cov kev tshuaj ntsuam.

(4) Coal zoo tsom xam: siv los txiav txim siab noo noo, tshauv, volatile cov ntsiab lus, tshauv melting point tsom xam, tshauv muaj pes tsawg leeg tsom xam, keeb tsom xam. Nws kuj tseem siv tau los ua lub tshuab hluav taws xob dav dav.

Cov saum toj no yog qhov kev siv ntawm muffle furnaces nrov los ntawm muffle furnace manufacturers.