- 21

- Feb

Ua hauj lwm hauv paus ntsiab lus ntawm induction melting rauv hauv ob sab phlu nrhiav kom paub ntaus ntawv

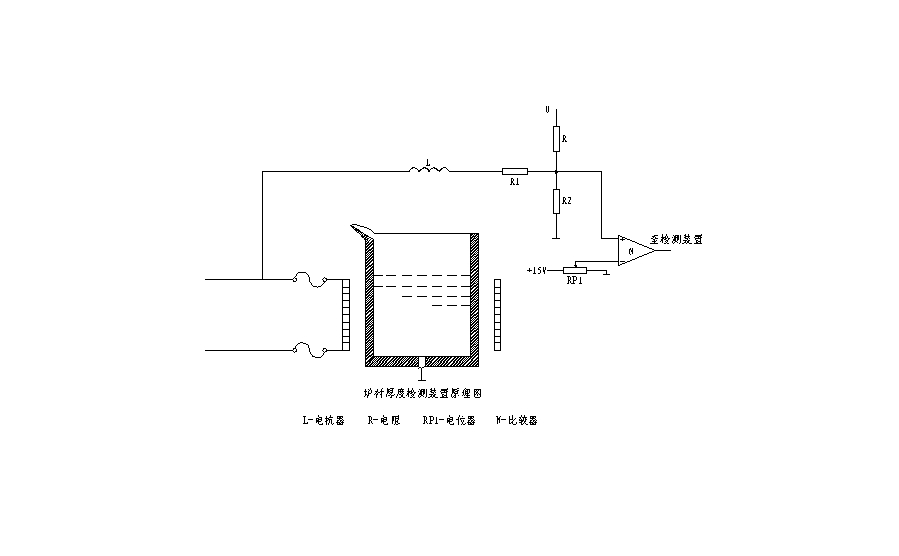

Daim ntawv thov ntawm cov khoom siv hauv ob sab phlu yuav tsum tau teeb tsa hauv qab electrode, raws li qhia hauv daim duab. Lub DC tsis tshua muaj hluav taws xob U yog ntxiv ntawm induction kauj thiab hauv av. Thaum lub qhov cub hauv ob sab phlu yog qhov qub, qhov kev tiv thaiv yog qhov loj, qhov tam sim no me me, thiab qhov sib txuam tsis sib xws ntawm cov khoom siv me me. Yog tias qhov tsis kam ntawm lub qhov cub hauv ob sab phlu tshwm sim (qhov thinning ntawm lub qhov cub hauv ob sab phlu thiab qhov loj ntawm qhov to ntawm cov hlau molten yuav ua rau tsis muaj kev tiv thaiv ntawm lub tshuab hluav taws xob hauv ob sab phlu), thiab qhov tam sim no loj heev, qhov sib thooj ntawm cov khoom siv tshuaj ntsuam yuav yog. loj, xws li cov ntaub ntawv loj heev kom tshaj lub tswb teev los ntawm cov neeg siv Parameters, lub tswb ntaus ntawv ua hauj lwm thiab lub tswb, qhov teeb liab no kuj yuav txuas mus rau lub zaus hloov dua siab tshiab ntaus ntawv kom nres, seb linkage yog txiav txim los ntawm tus neeg siv.

Daim ntawv thov ntawm cov khoom siv hauv ob sab phlu yuav tsum tau teeb tsa hauv qab electrode, raws li qhia hauv daim duab. Lub DC tsis tshua muaj hluav taws xob U yog ntxiv ntawm induction kauj thiab hauv av. Thaum lub qhov cub hauv ob sab phlu yog qhov qub, qhov kev tiv thaiv yog qhov loj, qhov tam sim no me me, thiab qhov sib txuam tsis sib xws ntawm cov khoom siv me me. Yog tias qhov tsis kam ntawm lub qhov cub hauv ob sab phlu tshwm sim (qhov thinning ntawm lub qhov cub hauv ob sab phlu thiab qhov loj ntawm qhov to ntawm cov hlau molten yuav ua rau tsis muaj kev tiv thaiv ntawm lub tshuab hluav taws xob hauv ob sab phlu), thiab qhov tam sim no loj heev, qhov sib thooj ntawm cov khoom siv tshuaj ntsuam yuav yog. loj, xws li cov ntaub ntawv loj heev kom tshaj lub tswb teev los ntawm cov neeg siv Parameters, lub tswb ntaus ntawv ua hauj lwm thiab lub tswb, qhov teeb liab no kuj yuav txuas mus rau lub zaus hloov dua siab tshiab ntaus ntawv kom nres, seb linkage yog txiav txim los ntawm tus neeg siv.