- 21

- Feb

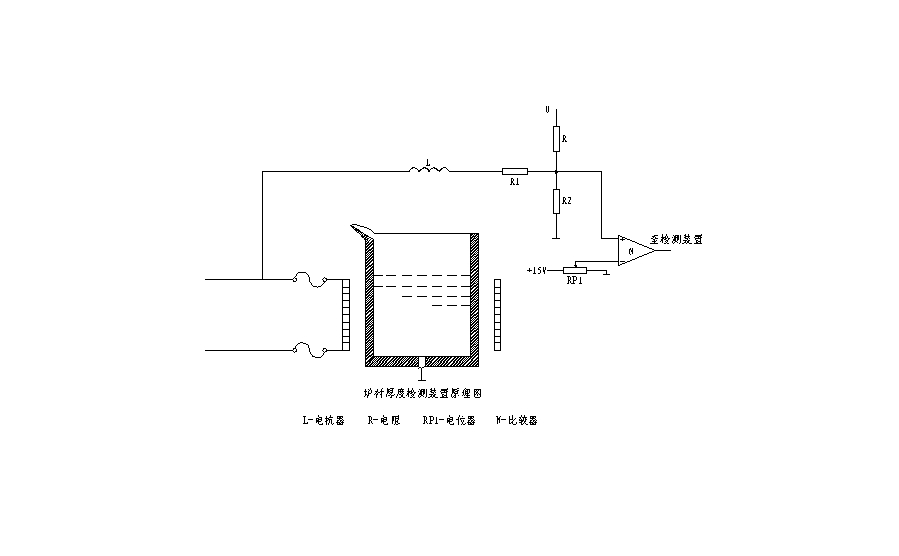

Working principle of induction melting furnace lining detection device

Working principle of induction melting furnace lining detection device

The application of the lining detection device requires the installation of the bottom electrode, as shown in the figure. The DC low voltage U is added between the induction coil and the ground. When the furnace lining is normal, the resistance is large, the current is small, and the corresponding parameters on the device display are small. If low resistance of the furnace lining occurs (the thinning of the furnace lining and the large-area leakage of molten metal will cause low resistance of the furnace lining), and the current is large, the corresponding parameters on the device display screen will be large, such as the data is too large to exceed the alarm set by the user Parameters, the alarm device works and alarms, this signal can also be linked to the frequency conversion device to stop, whether linkage is determined by the user.

The application of the lining detection device requires the installation of the bottom electrode, as shown in the figure. The DC low voltage U is added between the induction coil and the ground. When the furnace lining is normal, the resistance is large, the current is small, and the corresponding parameters on the device display are small. If low resistance of the furnace lining occurs (the thinning of the furnace lining and the large-area leakage of molten metal will cause low resistance of the furnace lining), and the current is large, the corresponding parameters on the device display screen will be large, such as the data is too large to exceed the alarm set by the user Parameters, the alarm device works and alarms, this signal can also be linked to the frequency conversion device to stop, whether linkage is determined by the user.