- 04

- Mar

Qhov tseem ceeb ntawm kev saib xyuas txhua hnub ntawm induction melting rauv

Qhov tseem ceeb ntawm kev saib xyuas txhua hnub ntawm induction melting rauv

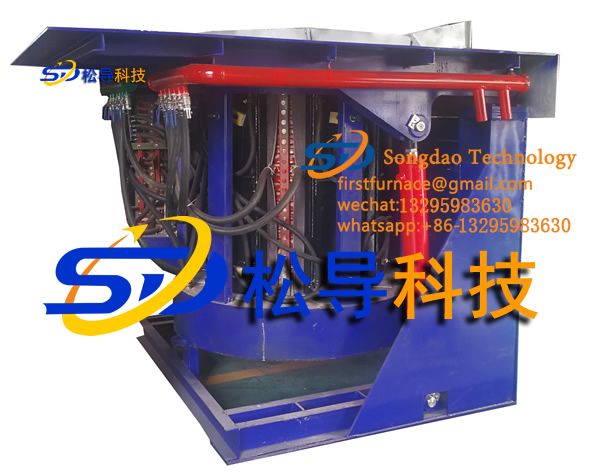

In the daily production of induction melting furnace, in addition to operating the induction melting furnace correctly and reasonably, the operating staff must also carefully and carefully do the daily maintenance of the induction melting furnace. During the operation of the induction melting furnace, due to system failure, component failure, mechanical loss or chemical corrosion, etc., it will inevitably cause abnormal operation. In order to avoid rapid damage and prevent the expansion of faults, maintenance work must be done during daily use.

Cov ntsiab lus tseem ceeb ntawm kev saib xyuas txhua hnub ntawm induction melting rauv yog ntxuav, tshem tawm plua plav, tiv thaiv corrosion thiab kho. Lub Hoobkas yuav tsum muab cov ntaub ntawv tsim nyog (xws li cov txheej txheem ua haujlwm, cov khoom siv tu thiab cov ntawv qhia, thiab lwm yam) rau cov neeg ua haujlwm induction melting furnace punch. Thaum lub qhov cub induction melting ua los ntawm Yuantuo Electromechanical yog xa mus rau cov neeg siv khoom

Lub sijhawm ntawd, peb yuav piav qhia rau cov neeg siv khoom txog cov teeb meem uas yuav tsum tau them nyiaj rau hauv kev saib xyuas ntawm induction melting rauv, uas zoo heev txhim kho lub neej kev pab cuam ntawm induction melting rauv.

Txhawm rau ua txoj haujlwm zoo ntawm kev saib xyuas, lub Hoobkas yuav tsum tsim ntau yam kev saib xyuas, tsis tu ncua tswj lub induction melting rauv, thiab ua kom haum rau kev txij nkawm raws li kev saib xyuas cov lus qhia muab los ntawm induction melting furnace chaw tsim tshuaj paus. Txawm li cas los xij, txawm li cas los xij, tsis muaj teeb meem dab tsi ntawm kev saib xyuas yog tsim los, lub peev xwm thiab cov ntsiab lus ntawm ntau yam kev tu vaj tse yuav tsum raug teev kom raug, thiab tshwj xeeb, ciam teb ntawm “kev tu” thiab “kho” yuav tsum txawv. Txwv tsis pub, nws yog ib qho yooj yim uas yuav ua rau disconnection los yog duplicate ntawm kev txij nkawm thiab kho, los yog vim muaj ntau yam thiab ntau cov ntsiab lus, qhov tseeb workload uas belongs rau cov kev tswj xyuas yog ib qho nyuaj rau ua raws li lub sij hawm ntev, thiab nws yog ib qho yooj yim mus ua hauj lwm. ua ib tug formality, thiab nws yuav coj quota kev tswj thiab kev npaj tswj. Muaj ntau inconveniences.

Feem ntau hais lus, lub luag haujlwm tseem ceeb ntawm kev saib xyuas yog tsim kom muaj qhov chaw ua haujlwm zoo rau lub qhov cub induction melting. Cov khoom tseem ceeb ntawm kev saib xyuas kev ua haujlwm yuav tsum tsis txhob muaj ntau dhau, yooj yim thiab ua tau yooj yim, qhov tseem ceeb yog kom muaj peev xwm nyob twj ywm rau lub sijhawm ntev. Feem ntau ntawm cov txij nkawm yog nyob rau sab nraud ntawm induction melting rauv, thiab tsis tas yuav disassemble, thiab tuaj yeem ua tiav yam tsis muaj kev cuam tshuam rau kev ua haujlwm, thiab tsis tas yuav txhob txwm npaj lub sijhawm tu. Cov khoom siv rau txhua txoj haujlwm tu tsis yog ntau dhau, yooj yim thiab yooj yim.