- 20

- May

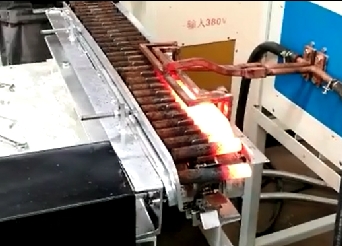

Hloov hlau induction cua sov rauv

Hloov hlau induction cua sov rauv

Round steel induction furnaces feem ntau yog siv rau cua sov forging ntawm puag ncig tuav thiab nplooj ntawv los txhim kho hlau thermoplasticity. Cov hlau cua sov ua haujlwm yog muab tso rau hauv induction coil ntawm alternating magnetic teb. Txij li thaum induction ncaj qha ua rau ntawm lub workpiece nws tus kheej los tsim eddy tam sim no thiab cua sov, lub round steel cua sov ntaus ntawv muaj lub sijhawm cua sov luv, tswj qhov kub thiab txias, lav qhov cua sov zoo, txhim kho kev ua haujlwm, thiab kev sib koom ua ke yooj yim. tsim tawm. Yog li ntawd, nws muaj ntau thiab ntau daim ntawv thov.

Summary of technical parameters of round steel induction cua sov rauv

| Tsis pub dhau 1000KW puag ncig induction rauv hluav taws xob technical parameters Cov ntsiab lus | |||||||

| Rated zog (KW) | Rated zaus (HZ) | Transformer muaj peev xwm (KVA) | Secondary voltage (V) | Number of commutating pulses | Sensor voltage (V) | Kev siv hluav taws xob (KW.h/t) | Round diam (mm) |

| 80 | 1000 ~ 8000 | 100 | 380v | 6 Pulse | 800 | 450 | Ib 6-35 |

| 100 | 1000 ~ 8000 | 160 | 380v | 6 Pulse | 800 | 450 | Ib 25-40 |

| 120 | 1000 ~ 8000 | 200 | 380v | 6 Pulse | 800 | 450 | Ib 30-50 |

| 160 | 1000 ~ 8000 | 250 | 380v | 6 Pulse | 800 | 450 | Ib 40-60 |

| 200 | 1000 ~ 8000 | 315 | 380v | 6 Pulse | 800 | 450 | Ib 40-60 |

| 250 | 1000 ~ 8000 | 400 | 380v | 6 Pulse | 800 | 450 | Ib 60-80 |

| 350 | 1000 ~ 8000 | 500 | 380v | 6 Pulse | 800 | 450 | Ib 80-120 |

| 400 | 500 ~ 8000 | 500 | 380v | 6 Pulse | 800 | 450 | Ib 80-120 |

| 500 | 500 ~ 8000 | 630 | 380v | 6 Pulse | 800 | 450 | Ib 120-150 |

| 1000 | 500 ~ 1000 | 1250 | 660V-380V | 12 Pulse | 1200 / 800 hli | 380 | Ib 150-250 |

| 1500 | 500 ~ 1000 | 1600 | Φ 660V-380V | 12 Pulse | 1200 / 800 hli | 370 | Ib 250-400 |

| 2000 | 500 ~ 1000 | 2200 | Φ 660V-380V | 12 Pulse | 1200 / 800 hli | 360 | Ib 400-800 |

Round steel induction cua sov rauv PLC ntse tswj qhov system:

1, tus neeg siv yuav tsum muab lub vijtsam kov lossis lub console tswj chaw taws teeb

2, txiv neej-tshuab interface, yooj yim rau kev khiav lag luam

3, kev hloov kho lub sijhawm ntawm cov cuab yeej ua haujlwm tsis zoo

4, real-time tswj cov txheej txheem cua sov, thiab muaj ib tug kaw muaj nuj nqi

5, txawv teb chaws hom lus hloov

Cov yam ntxwv tseem ceeb ntawm round steel induction cua sov rauv:

1. Nws yog siv rau cua sov ntau yam puag ncig steels xws li carbon steel thiab hlau;

2, nruab nrab zaus thiab super suab cua sov puag ncig steel, ntau rhuab, ntau yam thiab sai dua;

3, round steel induction cua sov rauv me me, txav tau yooj yim, tuaj yeem siv nrog cov khoom siv forging thiab dov;

4, induction cua sov qhov cub puag ncig bar yog rhuab mus rau qhov xav tau kub nyob rau hauv lub sij hawm luv luv ntawm lub sij hawm, zoo heev txo cov oxidation ntawm cov hlau, ob lub sij hawm thiab cov khoom, tab sis kuj txhim kho qhov zoo ntawm forging;

5, tsis siv neeg pub, tsis siv neeg pub, tsis siv neeg ntau lawm;

6. Qhov zoo ntawm round steel induction cua sov rauv rau lub zog txuag, kev tiv thaiv ib puag ncig, txo tus nqi thiab kev siv nyiaj txiag;

7. Nws yog qhov yooj yim los hloov lub sensor kom ua tau raws li qhov sib txawv ntawm cov cua sov tag nrho lossis qhov kawg cua sov ntawm cov hlau puag ncig.