- 20

- May

Insimbi yokufudumeza yensimbi eyindilinga

Insimbi yokufudumeza yensimbi eyindilinga

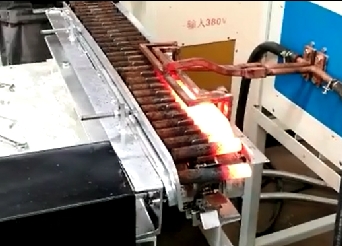

Izithando zokufakelwa zensimbi eziyindilinga zivame ukusetshenziselwa ukushisisa ukubumba imigoqo eyindilinga namashidi ukuze kuthuthukiswe i-thermoplasticity yensimbi. I-workpiece yokushisisa yensimbi ifakwa kukhoyili yokungeniswa yensimu kazibuthe eshintshanayo. Njengoba i-induction isebenza ngokuqondile kucezu lokusebenza ngokwayo ukukhiqiza i-eddy yamanje nokushisa, i- insiza yokushisa yensimbi eyindilinga inesikhathi esifushane sokushisisa, ukulawula izinga lokushisa esikahle, ikhwalithi yokushisa eqinisekisiwe, izimo zokusebenza ezithuthukisiwe, nokuhlanganiswa okulula. khiqiza. Ngakho-ke, inezinhlelo zokusebenza eziningi.

Isifinyezo semingcele yezobuchwepheshe yesithando somlilo esiyindilinga sokungeniswa kwensimbi

| Ngaphakathi kuka-1000KW amapharamitha wobuchwepheshe wokungeniswa kwesithando somlilo wesithando Isifinyezo | |||||||

| Amandla alinganiselwe(KW) | Isilinganiso sokuvama (HZ) | Umthamo we-Transformer (KVA) | I-voltage yesibili (V) | Inani lama-pulses ahambayo | I-voltage yenzwa(V) | Ukusetshenziswa kwamandla (KW.h/t) | I-roddiameter eyindilinga ( mm) |

| 80 | 1000 ~ 8000 | 100 | 380v | I-6 Pulse | 800 | 450 | Φ 6-35 |

| 100 | 1000 ~ 8000 | 160 | 380v | I-6 Pulse | 800 | 450 | Φ 25-40 |

| 120 | 1000 ~ 8000 | 200 | 380v | I-6 Pulse | 800 | 450 | Φ 30-50 |

| 160 | 1000 ~ 8000 | 250 | 380v | I-6 Pulse | 800 | 450 | Φ 40-60 |

| 200 | 1000 ~ 8000 | 315 | 380v | I-6 Pulse | 800 | 450 | Φ 40-60 |

| 250 | 1000 ~ 8000 | 400 | 380v | I-6 Pulse | 800 | 450 | Φ 60-80 |

| 350 | 1000 ~ 8000 | 500 | 380v | I-6 Pulse | 800 | 450 | Φ 80-120 |

| 400 | 500 ~ 8000 | 500 | 380v | I-6 Pulse | 800 | 450 | Φ 80-120 |

| 500 | 500 ~ 8000 | 630 | 380v | I-6 Pulse | 800 | 450 | Φ 120-150 |

| 1000 | 500 ~ 1000 | 1250 | 660V-380V | 12 Pulse | 1200 / (800) | 380 | Φ 150-250 |

| 1500 | 500 ~ 1000 | 1600 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 370 | Φ 250-400 |

| 2000 | 500 ~ 1000 | 2200 | Φ 660V-380V | 12 Pulse | 1200 / (800) | 360 | Φ 400-800 |

I-Round steel induction heat furnace PLC uhlelo lokulawula oluhlakaniphile:

1, umsebenzisi udinga ukuhlinzeka ngesikrini esithintwayo noma ikhonsoli yesilawuli kude

2, isikhombimsebenzisi somshini womuntu, kulula ukusebenza

I-3, ukulungiswa kwesikhathi sangempela kwemingcele yokusebenza kwemishini

I-4, ukulawulwa kwesikhathi sangempela kwenqubo yokushisa, futhi inomsebenzi wokurekhoda

5, ukushintsha kolimi lwamazwe ngamazwe okuhlukile

Izici eziyinhloko zesithando sokushisa sensimbi esiyindilinga:

1. Isetshenziselwa ukufudumeza izinsimbi ezihlukahlukene eziyindilinga njenge-carbon steel nensimbi;

I-2, imvamisa ephakathi nendawo kanye nokushisa okulalelwayo okuphezulu okuzungezile, ukufudumeza okwengeziwe, iyunifomu eyengeziwe futhi ngokushesha;

I-3, insimbi eyindilinga yokushisa isithando somlilo esincanyana, kulula ukuyihambisa, ingasetshenziswa nanoma iyiphi imishini yokubumba nokugingqa;

I-4, ibha eyindilinga yokushisisa kahhavini wokungenisa ukushisa ishisiswe ekushiseni okufunayo ngesikhathi esifushane kakhulu, inciphisa kakhulu i-oxidation yensimbi, kokubili isikhathi nezinto ezibonakalayo kodwa futhi ithuthukisa ikhwalithi yokubumba;

I-5, ukuphakela okuzenzakalelayo, ukuphakela okuzenzakalelayo, umthamo wokukhiqiza okuzenzakalelayo;

6. Izinzuzo zesithando somlilo esiyindilinga sokungeniswa kwensimbi okonga amandla, ukuvikelwa kwemvelo, ukunciphisa izindleko kanye nezindleko zabasebenzi;

7. Kuhle ukufaka esikhundleni senzwa ukuze kuhlangatshezwane nezidingo ezahlukene zokushisa okuphelele noma ukuphela kokushisa kwensimbi eyindilinga.