- 03

- Aug

Xaiv txoj kev ntawm aluminium plhaub steel plhaub induction melting rauv

- 03

- Aug

- 03

- Aug

Xaiv txoj kev ntawm aluminium plhaub steel plhaub induction melting rauv

Induction rauv lub cev muaj xws li hluav taws xob rauv lub cev, dej-txias cable, refractory cement, hluav taws xob tilting rauv, thiab lwm yam.

![14-1 [1]](https://songdaokeji.cn/wp-content/uploads/2022/08/2022080300403595.jpeg)

Schematic daim duab tso rau nruab nrab zaus fais fab mov txee, capacitor txee thiab melting furnaces

1. Rauv

Lub tshuab ua kom sov lub cev yog tsim los ntawm induction coil, aluminium alloy rauv plhaub, hluav taws xob rauv tilting ntaus ntawv, thiab lwm yam.

6.1.1 Induction kauj

Lub induction kauj yog ua los ntawm 99.99% T2 lub raj tooj liab. Cov rwb thaiv tsev saum npoo ntawm induction coil yog txau nrog txheej txheej ntawm lub zog siab epoxy insulating resin los ntawm cov txheej txheem electrostatic txau, thiab daim kab xev mica yog qhwv thiab qhwv nrog daim ntaub dawb rau kev kho mob immersion, txheej rwb thaiv tsev tiv thaiv voltage ntau dua 5000V. .

Lub induction kauj yog tsau los ntawm ib tug series ntawm bolts thiab insulating nyob twj ywm welded ntawm nws sab ib ncig. Tom qab lub kauj yog tsau, qhov yuam kev ntawm nws tig lub suab tsis ntau tshaj 1.5 hli.

2. Parameters ntawm induction kauj thiab nqi

Cov tsis muaj induction kauj thiab tus nqi yog optimized thiab tsim nrog tshwj xeeb computer software. Nws tuaj yeem ua kom qhov zoo tshaj plaws electromagnetic coupling efficiency nyob rau hauv tib lub peev xwm. Muab rau hauv tus account tias lub cub hluav taws xob yuav tsum tau muab tso rau ntau tshaj, lub peev xwm ntsuas yog qhov loj me me dua li lub peev xwm nominal hauv kev tsim. Tsuas yog nyob rau hauv txoj kev no nws tuaj yeem ua kom ntseeg tau tias cov kua theem ntawm tus nqi tsis tshaj lub dav hlau sab saud ntawm lub nplhaib dej-txias thaum lub cub hluav taws xob nyob ntawm qhov nyiaj them siab tshaj plaws. Vim hais tias ib feem ntawm lub qhov cub hauv ob sab phlu saum lub nplhaib dej-txias tsis txias, yog tias qhov no yog nyob rau hauv kev sib cuag nrog tus nqi ntev, qhov kub thiab txias yuav raug tsim, uas yuav ua rau lub qhov cub hauv ob sab phlu tuaj yeem tawg ntawm cov dej sab saud. – lub nplhaib txias.

3. Dej-txias cable

Qhov sib koom ua ke ntawm cov dej-txias cable yog crimped nrog tooj liab stranded hlau siv cov txheej txheem txias txias. Nyob rau hauv txoj kev no, kev sib txuas yog ruaj khov, kev tiv thaiv kev tiv thaiv yog me me, thiab cov tooj liab stranded hlau tsis puas. Ib qho kev sib koom ua ke thiab cov hlau tooj liab tuaj yeem tiv taus lub zog tensile ntau tshaj 8t. Lub raj sab nraud ntawm cov dej-txias cable txais yuav ib lub raj roj hmab tshwj xeeb. Hom hose no tsis yooj yim rau hlawv thiab muaj lub zog zoo. Nws tuaj yeem tiv taus 0.5Mpa dej siab yam tsis muaj dej los yog tawg.

Dej txias dej

4. Refractory mortar

Lub coil cement yog ua los ntawm cov khoom tshwj xeeb refractory cement rau cov coils ntawm US Allied Mines smelting rauv, uas muaj cov yam ntxwv ntawm lub zog zoo, kub tsis kam, thiab zoo rwb thaiv tsev.

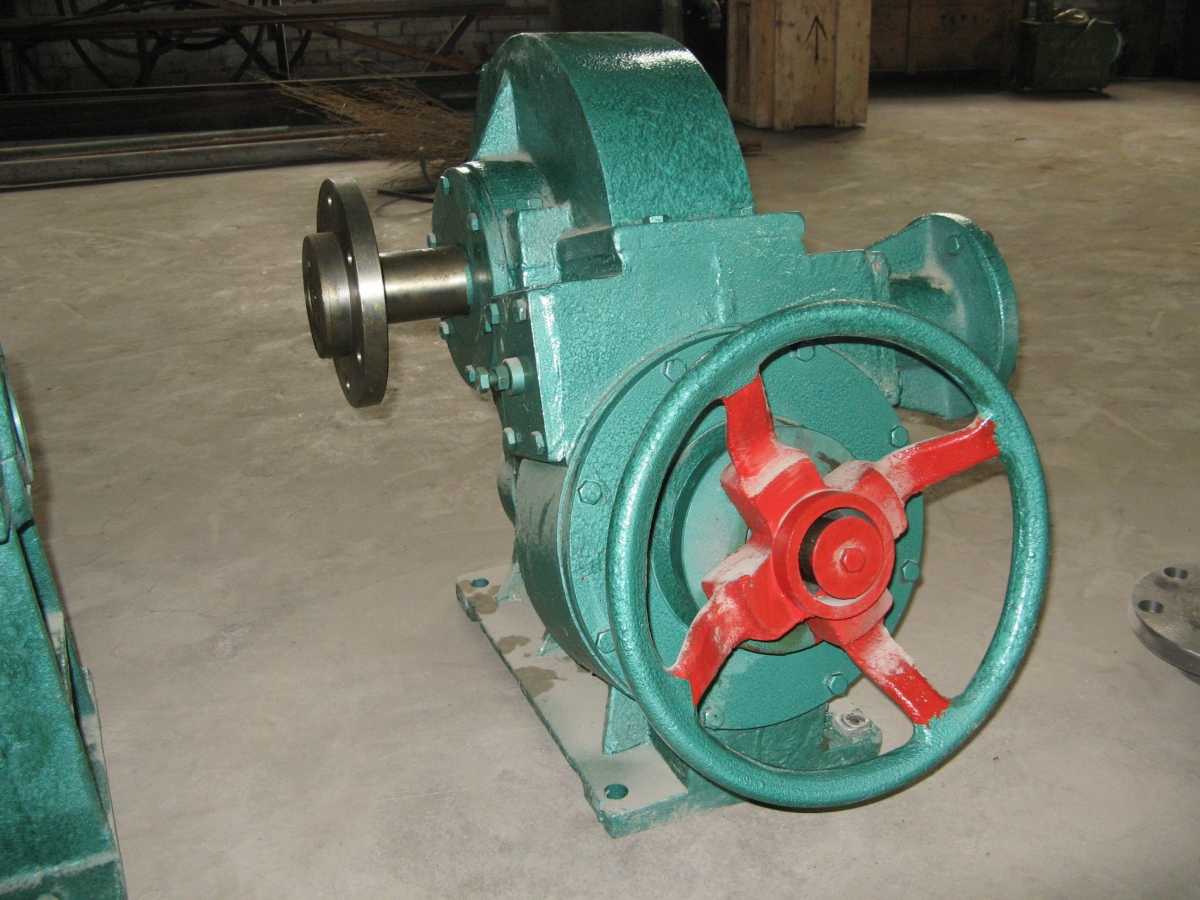

5. Lub reducer rau tilting rauv txais qhov tshwj xeeb reducer rau induction rauv uas tsim los ntawm cov tuam txhab lag luam paub zoo, nrog cov tilting ceev thiab txhim khu kev qha zoo. Lub tilting ntawm lub cub tawg lub cev ntawm lub nruab nrab zaus hluav taws xob rauv yog ncaj qha tsav los ntawm lub tilting rauv txo lub thawv. Lub tilting rauv reducer yog ob-theem worm iav nrog kev ua haujlwm zoo ntawm tus kheej thiab kev sib hloov ruaj khov thiab txhim khu kev qha. Nyob rau hauv rooj plaub thaum muaj xwm txheej ceev tsis ua hauj lwm, lub cub tawg tuaj yeem tig tau manually kom tsis txhob muaj kev phom sij ntawm kev kub hnyiab vim qhov kub ntawm lub cub tawg ntau dhau.

Reducer