- 03

- Aug

Indlela yokukhetha iqokobhe le-aluminiyam iqokobhe lentsimbi yokunyuselwa kwiziko lokunyibilikisa

- 03

- Aug

- 03

- Aug

Indlela yokukhetha iqokobhe lentsimbi ye-aluminium ukuchithwa kwesithando somlilo

Umzimba wesithando somlilo we-induction ubandakanya umzimba wesithando sombane, intambo epholileyo ngamanzi, isamente ekhanyelayo, inkqubo yombane yokuthamba, njl.

![14-1 [1]](https://songdaokeji.cn/wp-content/uploads/2022/08/2022080300403595.jpeg)

Umzobo ocwangcisiweyo wokubekwa kweekhabhathi zobonelelo lwamandla ngamaxesha aphakathi, iikhabhathi zecapacitor kunye neziko lokunyibilika

1. Iziko

Umzimba wesithando somlilo wenziwa nge-coil induction, igobolondo le-aluminium alloy furnace, isixhobo sokuthambeka kwesithando sombane, njl.

6.1.1 Ikhoyili yokuqhelanisa

I-coil induction yenziwe nge-99.99% ye-T2 ityhubhu yethusi yoxande. Ukugqunyelelwa komphezulu wecoil yokungeniswa kutshizwa ngomaleko we-epoxy insulating resin ephezulu kakhulu ngenkqubo yokutshiza nge-electrostatic, kwaye i tape ye-mica isongelwe emva koko isongelwe ngeteyiphu emhlophe yelaphu lonyango lokuntywiliselwa, umaleko wokugquma Umbane wokumelana mkhulu kune-5000V. .

Ikhoyili ye-induction igxininiswe ngoluhlu lweebholiti kunye ne-insulating zihlala zifakwe kwi-circumference yayo yangaphandle. Emva kokuba ikhoyili ilungisiwe, impazamo ye-turn pitch yayo ayikho ngaphezu kwe-1.5mm.

2. Iiparamitha zekhoyili ye-induction kunye nentlawulo

Iiparamitha ze-coil induction kunye nentlawulo ziphuculwe kwaye ziyilwe ngesoftware ekhethekileyo yekhompyuter. Inokuqinisekisa eyona nto isebenzayo yokudibanisa i-electromagnetic phantsi komthamo ofanayo. Ukuthathela ingqalelo ukuba isithando somlilo sombane kufuneka sifakwe ngaphezulu, umthamo olinganisiweyo wenziwe mkhulu kancinci kunomthamo wegama kuyilo. Kuphela ngale ndlela inokuqinisekiswa ukuba umgangatho we-liquid wentlawulo awudluli kwi-plane ephezulu yendandatho epholileyo yamanzi xa isithando sombane sikwixabiso eliphezulu lokutshaja. Ngenxa yokuba inxalenye yesithando somlilo ngaphezu kwendandatho epholileyo yamanzi ayipholiswanga, ukuba le nxalenye idibene nentlawulo ixesha elide, ukushisa okuphezulu kuya kuveliswa, okuya kubangela ukuba umbane wesithando somlilo uqhekeke emanzini aphezulu. -umsesane opholileyo.

3. Intambo epholileyo ngamanzi

I-joint of the cable-cooled cable is crimped kunye ne-copper stranded wire usebenzisa inkqubo yokubumba ebandayo. Ngale ndlela, uxhulumaniso luqinile, ukuchasana koqhagamshelwano kuncinci, kwaye ucingo oluxutywe nobhedu alonakali. Umdibaniso omnye kunye nocingo lobhedu lunokumelana ne-tensile force engaphezulu kwe-8t. Ityhubhu yangaphandle yentambo epholileyo yamanzi ithatha ityhubhu ekhethekileyo yerabha evuthayo. Olu hlobo lombhobho alulula ukutshisa kwaye lunamandla amahle. Inokumelana noxinzelelo lwamanzi lwe-0.5Mpa ngaphandle kokuvuza okanye ukugqabhuka.

Intambo epholileyo yamanzi

4. Udaka lweRefractory

Ikhoyili yesamente yenziwe ngesamente ekhethekileyo yokunqanda iikhoyili ze-US Allied Mines smelting furnace, eneempawu zamandla amahle, ukumelana nobushushu obuphezulu, kunye nokugquma okulungileyo.

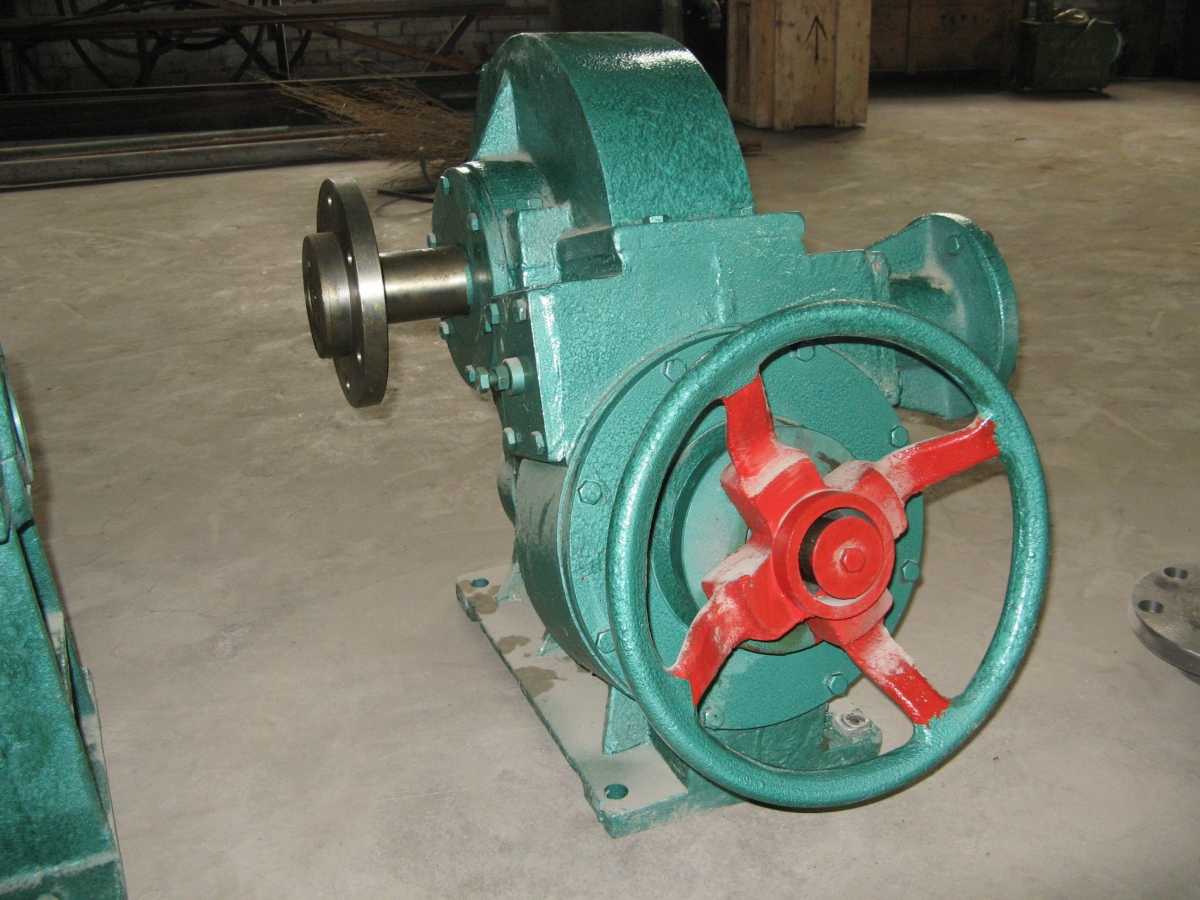

5. Isinciphisi se-tilting furnace sithatha isinciphisi esikhethekileyo sesithando somlilo esiveliswe ngabavelisi basekhaya abaziwayo, kunye nesantya esilinganayo sokuthamba kunye nomgangatho othembekileyo. I-tilting ye-furnace body of the intermediate frequency electric furnace iqhutywa ngokuthe ngqo yibhokisi yokunciphisa isithando somlilo. I-tilting furnace reducer yigiya yeentshulube enamanqanaba amabini kunye nokusebenza kakuhle kokuzivalela kunye nokujikeleza okuzinzileyo nokuthembekileyo. Kwimeko yokungaphumeleli kwamandla kaxakeka, isithando somlilo sinokuthotywa ngesandla ukuze siphephe ingozi yokutshisa i-coil ngenxa yokushisa okugqithisileyo kwisithando somlilo.

Nciphisa