- 13

- Sep

Xaiv txoj kev me me melting khoom

xaiv txoj kev me me melting khoom

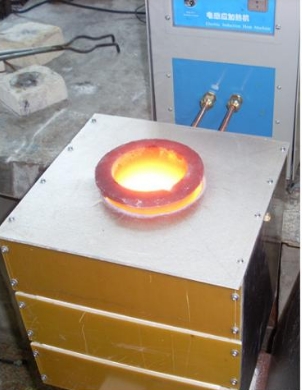

Cov khoom siv me me, melting ceev ceev, tsis muaj nplaim taws, siv tsawg, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, me me, kev ua haujlwm yooj yim, tsis muaj plua plav, tsis poob, tsis muaj teeb meem rau lub cev, muaj kev nyab xeeb thiab txhim khu kev qha. Nws tuaj yeem siv ncaj qha los ntawm kev sib txuas hluav taws xob thiab dej tsis muaj kev debugging, thiab kev ua haujlwm ntawm lub tshuab yog yooj yim heev hauv 10 feeb;

Cov hom ntawm melting furnaces yog:

1. High-frequency melting rauv, lub hwj chim ntawm 7kw-15kW melts 1kg, 2kg, 4kg integrated/split tabletop melting rauv, integrated/split clamp hom melting rauv.

2. Intermediate zaus melting rauv, lub zog ntau yog 15kw-160kW kom yaj 5kg, 10kg, 20kg, 30kg, 50kg, 100kg, 120kg, 150kg, 200kg tsau melting rauv, phau ntawv tilting melting furnace, tawm melting rauv.

Lub tshuab hluav taws xob me me induction melting rauv ua los ntawm Zhenjiang Tianxiang Lub Tuam Txhab muaj qhov nrawm nrawm, kev siv hluav taws xob tsawg thiab kev tiv thaiv ib puag ncig, me me, kev ua haujlwm yooj yim, tsis muaj plua plav, tsis poob, tsis muaj mob rau lub cev, tsis cuam tshuam rau cov cuab yeej precision, kev nyab xeeb thiab txhim khu kev qha, thiab melting muaj peev xwm Los ntawm kaum ntawm grams mus rau 200 kilograms, muaj ntau yam kev xaiv. Nws yog tsim rau melting hlau, hlau, tooj liab, txhuas, zinc thiab ntau yam hlau muaj nuj nqis kub thiab nyiaj. Nws yog siv nyob rau hauv tsev kawm ntawv lub chaw soj nstuam, kev tshawb fawb lub koom haum, cov hniav nyiaj hniav kub ua, thiab pwm. Factory, hlau ua lag luam, casting ua, me me melting ua, me me batch ntau lawm, tus kheej tes rhiav hom ntau lawm, tsev kawm ntawv melting xyaum, melting xyaum ua tej yam kev tshawb fawb lub tsev, precious hlau purification, kub bar thiab nyiaj bar ntau lawm thiab lwm zaus. Nws tag nrho daws cov teeb meem ntawm coke cua sov thiab roj Qhov tsis zoo ntawm cov txheej txheem melting qub xws li cua sov yog cov khoom siv zoo tshaj plaws rau lub cim tshiab ntawm cov hlau melting. Rau

Feature ntawm melting rauv:

1. Cov txheej txheem cua sov: siv magnetic teb induction cua sov txoj kev, hlau purification kuj muaj txiaj ntsig zoo heev.

2. Cov hom phiaj: (hlau kub) nyiaj, tooj liab, hlau, txhuas, zinc, tin, antimony, npib tsib xee, thiab ntau yam alloys (non-metallic) silicon, polysilicon, thiab rhuab graphite pwm, thiab lwm yam.

3. Lub tshuab cua sov lub cev: graphite crucible, quartz xuab zeb crucible, magnesia xuab zeb casting crucible, ceramic crucible, cam khwb cia hlau crucible, thiab lwm yam.

4. Main accessories: tswj Circuit Court boards ntawm nws tus kheej tsim los ntawm lub tuam txhab, raws li zoo raws li modules, rectifier txuas hniav thiab lwm yam accessories los ntawm cov loj-paub manufacturers.

5. Kev them nyiaj yug Load: 100% load continuity rate, nce lub sij hawm thiab nyiaj tau los rau lub lag luam

6. Cua sov ceev: ceev cua kub ceev, tsim nyog npaum li cas rau yaj lub melting point rau 10-30 feeb, thiab siab melting point rau yaj rau 40-50 feeb

7. Rauv kub: ntau tshaj 1200-1600 degrees, qhov kub ntawm polysilicon tuaj yeem yaj.

8. Kev txhawb nqa kev txhim kho: kev hloov kho xws li kev tswj qhov kub thiab txias tuaj yeem tsim tau, thiab cov neeg siv khoom xav tau tuaj yeem txhawb nqa rau qee yam.

Zhenjiang Tianxiang lub lag luam tseem ceeb: tooj liab melting rauv, kub melting rauv, aluminium melting rauv, nyiaj melting rauv, sim tshiab melting rauv, high-frequency vuam tshuab, annealing tshuab, quenching tshuab, forging cua sov tshuab, induction cua sov tshuab, cua sov kho cua sov khoom , Hlau marking tshuab, hluav taws xob ntawv cwj mem, tapping tshuab, twist laum dov tshuab