- 13

- Sep

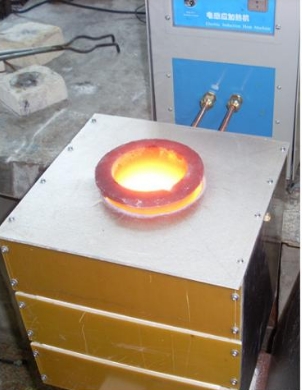

Selection method of small melting equipment

Selection method of small melting equipment

Small melting equipment, fast melting speed, no open flame, low consumption, energy saving and environmental protection, small size, simple operation, no dust, no loss, harmless to the body, safe and reliable. It can be used by directly connecting the electricity and water without debugging, and the operation of the machine is very simple in 10 minutes;

The types of melting furnaces are:

1. High-frequency melting furnace, the power of 7kw-15kW melts 1kg, 2kg, 4kg integrated/split tabletop melting furnace, integrated/split clamp type melting furnace.

2. Intermediate frequency melting furnace, the power range is 15kw-160kW to melt 5kg, 10kg, 20kg, 30kg, 50kg, 100kg, 120kg, 150kg, 200kg fixed melting furnace, manual tilting melting furnace, electric tilting melting furnace, pneumatic Top-out melting furnace.

The small electromagnetic induction melting furnace produced by Zhenjiang Tianxiang Company has fast melting speed, low energy consumption and environmental protection, small size, simple operation, no dust, no loss, harmless to the body, no effect on precision instruments, safe and reliable, and melting capacity From tens of grams to 200 kilograms, there is a wide range of options. It is suitable for melting iron, steel, copper, aluminum, zinc and various precious metals gold and silver. It is used in university laboratories, research institutes, jewelry processing, and molds. Factory, metal processing enterprise, casting processing, small melting processing, small batch production, personal hand workshop type production, school melting experiment, melting experiment of scientific research institution, precious metal purification, gold bar and silver bar production and other occasions. It completely solves the problem of coke heating and gas The disadvantages of the original melting process such as heating are the ideal equipment for a new generation of metal melting. To

Features of melting furnace:

1. Heating method: using magnetic field induction heating method, metal purification also has a very good effect.

2. Targets: (metallic gold) silver, copper, iron, aluminum, zinc, tin, antimony, nickel, and various alloys (non-metallic) silicon, polysilicon, and heated graphite molds, etc.

3. Heating furnace body: graphite crucible, quartz sand crucible, magnesia sand casting crucible, ceramic crucible, cast iron crucible, etc. (different crucibles are equipped according to the melt of different metals)

4. Main accessories: control circuit boards independently developed by the company, as well as modules, rectifier bridges and other accessories from major well-known manufacturers

5. Load support: 100% load continuity rate, gain time and profit for the enterprise

6. Heating speed: fast heating speed, suitable amount to melt the low melting point for 10-30 minutes, and the high melting point to melt for 40-50 minutes

7. Furnace temperature: more than 1200-1600 degrees, the temperature at which polysilicon can be melted

8. Support improvement: modifications such as temperature control can be designed, and customer customization requirements can be supported to a certain extent

Zhenjiang Tianxiang’s main business: copper melting furnace, gold melting furnace, aluminum melting furnace, silver melting furnace, experimental new melting furnace, high-frequency welding machine, annealing machine, quenching machine, forging heating machine, induction heating machine, heat treatment heating equipment, Metal marking machine, electric lettering pen, tapping machine, twist drill rolling machine