- 13

- Feb

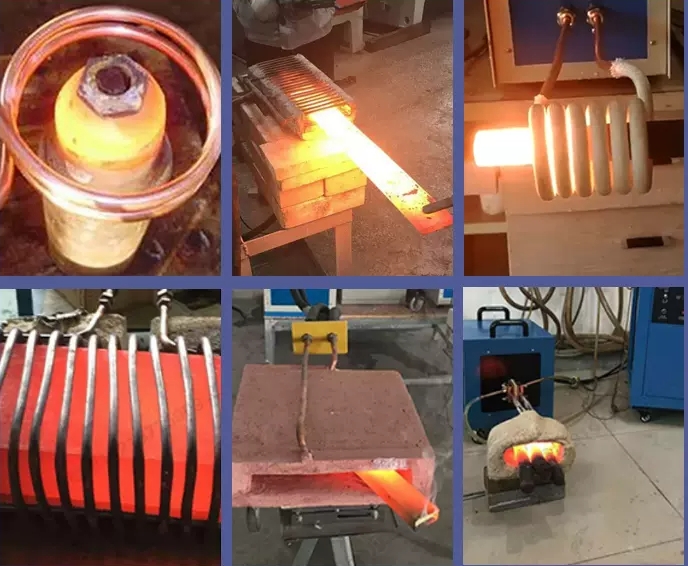

High frequency induction heating equipment should be quickly tempered after quenching

High frequency induction heating equipment should be quickly tempered after quenching

The influence of high-frequency induction heating equipment after quenching and tempering is not timely on the quality of the entire product, the effect is different according to different steel types, and cannot be generalized. After the steel is quenched, the martensite structure is obtained. Depending on the carbon content, there may be residual austenite or carbide generation. Since the structure (except carbide) is a metastable structure, there is a tendency to transform to a stable structure at room temperature. , the tempering after quenching only accelerates this trend.

At the same time, quenching produces a large internal stress, whether it is caused by structural stress or thermal stress, it will remain in the steel to form internal stress. Unstable structure + residual internal stress, this is the condition after quenching.

1. For medium carbon steel, due to the small stress of the quenched structure and good strength and toughness, the problem of not tempering in time is not very big, that is, the time interval should not be too long, and the unstable structure will change if the time is too long. The stress will increase the risk of deformation cracking. Therefore, it is best to temper in time, and those that cannot be tempered in time should not exceed 24 hours.

2. For low-carbon martensitic steel, due to the small stress of the quenched structure and good strength and toughness, it is not a big problem if it is not tempered in time, and it can even be used directly without tempering.