- 16

- Nov

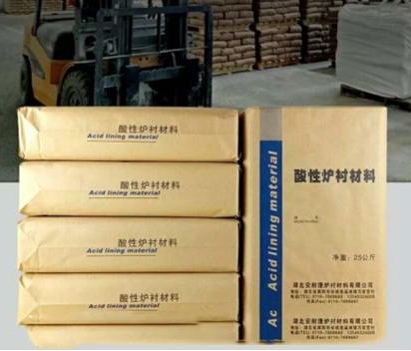

Ihe mkpuchi mkpuchi ọkụ induction

Ihe mkpuchi mkpuchi ọkụ induction

Ihe na-eme ka ọkụ na-ekpo ọkụ bụ mkpuchi ọkụ a bụ ihe agwakọtara nke ọma. A na-ahọrọ ihe nkedo dị elu nke dị elu ka ọ nwee nguzogide mgbape siri ike. Uzuzu quartz dị elu na ịdị ọcha dị elu na quartz ntụ ntụ nwere nnukwu nguzogide okpomọkụ, na oke okpomọkụ nwere ike iru ogo 2000. , A na-eji ya na-arụ ọrụ na-aga n’ihu na gburugburu ebe ọrụ na-adịghị agwụ agwụ nke ọla ndị na-adịghị ferrous na ọla ndị na-emepụta ihe.

A na-eji ihe ọkụkụ, nnọpụiche, na alkaline ramming eme ihe n’ọtụtụ ebe n’ime ọkụ induction na-enweghị isi yana ọkụ induction cored. A na-eji ha dị ka induction ọkụ ramming ihe na-agbaze nkedo isi awọ, ductile iron, forgeable nkedo ígwè, vermicular graphite nkedo ígwè na nkedo ígwè alloys. , Na-agbaze carbon ígwè, alloy ígwè, elu manganese ígwè, ngwá ọrụ ígwè, okpomọkụ na-eguzogide ígwè, igwe anaghị agba nchara, agbaze aluminum na ya alloys, agbaze ọla kọpa alloys dị ka ọla kọpa, brass, cupronickel na bronze, wdg.

N’iji ájá quartz dị elu dị ka akụrụngwa bụ isi, ihe ndị ahụ na-adị n’ọtụtụ ọkwa, kwadebere ya na ihe akọrọ, wee kpalie. Mee ka usoro ihicha na sintering dị mkpụmkpụ. Ndị ọrụ nwere ike rụọ nnukwu ọkụ n’ekwughị ọkụ.

O nwere njirimara nke enweghị mkpọtụ, enweghị mgbawa, enweghị ọdịda mgbe ekpughere ya na iru mmiri, nrụzi ọkụ dị ọkụ, na nguzogide corrosion, ọkachasị nwere ike melite afọ ọkụ, ma meziwanye uru akụ na ụba. Companylọ ọrụ ahụ na -enye nnukwu ihe mkpuchi silik, a na -ekwe nkwa ịdị mma ya. Nabata ka ị gbaa izu ma kpaa nkata!

A na -eji ihe ụdị ZG1 agbaze usoro ihe igwe dị ka nchara nkịtị, nchara 45#, nchara gong dị elu, nchara manganese dị elu, nchara pụrụ iche, wdg. iru 120 heats.

A na -eji ihe eji eme ihe ZH2 agbaze agba ntụ, ọnụọgụ ọkụ a na -eji eme ihe nwere ike iru ihe karịrị ọkụ ọkụ 300, nke kachasị nwere ike iru ọkụ ọkụ 550.