- 16

- Nov

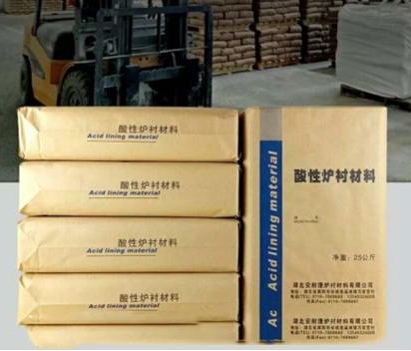

Induction furnace lining material

Induction furnace lining material

Bahan ramming Lapisan tungku ieu mangrupikeun bahan ramming garing anu tos dicampur. Binder suhu luhur kualitas luhur kapilih ngagaduhan résistansi retakan anu kuat. Pasir kuarsa kualitas luhur sareng purity murni sareng bubuk quartz ngagaduhan résistansi suhu luhur, sareng suhu maksimum tiasa ngahontal 2000 derajat. , Éta seueur dianggo dina operasi kontinyu sareng lingkungan operasi intermitén tina logam non-ferrous sareng logam ferrous.

Bahan ramming asam, nétral, sareng basa seueur dianggo dina tungku induksi tanpa korosi sareng tungku induksi cored. Éta dipaké salaku bahan ramming tungku induksi pikeun ngalembereh beusi tuang abu, beusi saluran, beusi tuang anu tiasa didamel, beusi corétan grafit vermikut sareng campuran wesi tuang. , Ngalebur baja karbon, baja paduan, baja mangan tinggi, baja alat, baja tahan panas, stainless steel, lebur aluminium sareng paduanna, ngalebur alloy tambaga sapertos tambaga, kuningan, cupronickel sareng gangsa, jst.

Using high-quality quartz sand as the main raw material, the particles are in a multi-level ratio, prepared with dry materials, and stirred evenly. Shorten the drying and sintering cycle. Users can build the furnace directly without stirring.

It has the characteristics of no slagging, no cracking, no failure when exposed to moisture, convenient repair of the furnace, and corrosion resistance, especially can improve the age of the furnace, and significantly improve economic benefits. The company supplies a large amount of silicon ramming materials, and the quality is guaranteed. Welcome to consult and negotiate!

Bahan jenis ZG1 digunakeun pikeun ngalembereh sapérangan bahan logam sapertos baja biasa, 45 # waja, waja gong tinggi, waja mangan tinggi, waja khusus, sareng sajabana Jumlah panén anu dianggo tiasa ngahontal langkung ti 120 heats, sareng kaléng anu pangluhurna ngahontal 195 manaskeun.

The ZH2 type material is used for smelting gray iron, and the number of furnaces used can reach more than 300 furnaces, and the maximum can reach 550 furnaces.