- 09

- Dec

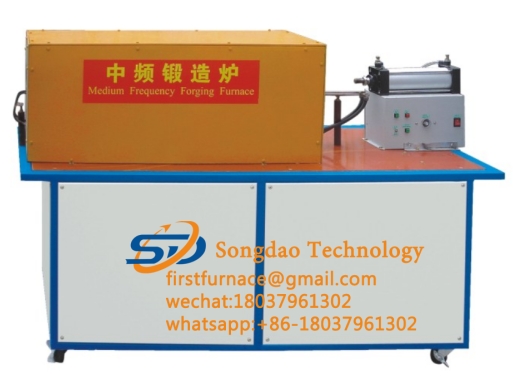

Igwe anaghị agba nchara etiti oge ọkụ ọkụ

Igwe anaghị agba nchara etiti oge ọkụ ọkụ

Nhazi na njirimara nke igwe anaghị agba nchara etiti oge ọkụ ọkụ:

● Sistemụ ọkọnọ ike: 200KW-6000KW ma ọ bụ IGBT200KW-IGBT2000KW, na mmepụta elekere nke 0.2-16 tọn.

● Sistemụ kpo oku induction: Dị ka mkpa gị si dị, hazie imewe nke inductor, nha nke workpiece size, udi na size nke induction anụ ọkụ ahụ, a na-achịkwa okpomọkụ nke ọkụ ahụ, na-azọpụta ike, na-arụ ọrụ dị elu, na ngwa ngwa.

● Usoro nchekwa: A na-agbakọta tubes square nwere mgbidi ka ọ bụrụ ebe a na-echekwa ihe, na-enwe mmasị nke ogo 13, nke nwere ike ịchekwa ihe karịrị 20 ihe.

● Usoro njikwa okpomọkụ: Infrared okpomọkụ nha PLC okpomọkụ mechiri akaghị aka akpaka okpomọkụ akara usoro.

● PLC njikwa: ahaziri nke ọma mmadụ-igwe interface, ukwuu ọrụ-enyi na enyi ntuziaka ọrụ, ime ime ihe njikwa nke sistemu kọmputa ụlọ ọrụ na ihuenyo mmetụ, ihe niile-dijitalụ elu-omimi nke mgbanwe parameters, na-eme ka ị na-ejikwa ngwa ọzọ kemfe. Enwere sistemu mweghachi nke otu igodo yana ọrụ ngbanwe ọtụtụ asụsụ.

● Roller conveyor sistemu: na-anabata usoro mbugharị na-atụgharị, axis nke roller na axis nke workpiece na-etolite akụkụ nke ogo 18-21, okpokoro rola n’etiti ahụ ọkụ bụ nke 304 na-abụghị igwe anaghị agba nchara na mmiri. mma, na workpiece na-ewe iwe evenly.

▲ Ntughari ike: kpo oku igwe nke ọ bụla ruo 1050 ° C, oriri ike 310-330C.