- 09

- Dec

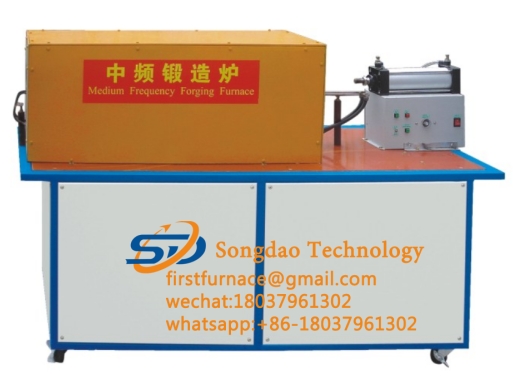

Foornada kululaynta inta jeer ee birta ah ee dhexdhexaadka ah

Foornada kululaynta inta jeer ee birta ah ee dhexdhexaadka ah

Habaynta iyo sifooyinka foornada kululaynta ee inta jeer ee birta ah ee dhexdhexaadka ah:

● Nidaamka sahayda korontada: 200KW-6000KW ama IGBT200KW-IGBT2000KW, oo leh saacadii wax soo saarka 0.2-16 tan.

● Nidaamka kuleyliyaha Induction: Marka loo eego baahiyahaaga, habbee naqshadeynta soo saaraha, cabbirka cabbirka shaqada, qaabka iyo cabbirka jirka foornada induction, heerkulka jidhka foornada waa la kontarooli karaa, tamar-badbaadin, hufnaan sare leh, oo degdega.

● Habka kaydinta: tuubooyinka labajibbaaran ee dhumuc weyn ayaa la alxanayaa si ay u sameeyaan meel wax lagu kaydiyo, oo u janjeedha 13 digrii, kaas oo kaydin kara in ka badan 20 walxood.

● Nidaamka xakamaynta heerkulka: Cabbiraadda heerkulka Infrared PLC heerkulka xidhmay si toos ah nidaamka heerkulka.

● PLC control: interface man-chine interface oo si gaar ah loo habeeyay, hab-raac adeegsi-saaxiibtinimo oo heersare ah, console-ka hawlgalka fog-fog ee nidaamka kombuyuutarrada warshadaha oo leh shaashad taabasho ah, cabbirro qoto-dheer oo qotodheer oo dijitaal ah oo dhan, taasoo kaa dhigaysa inaad gacanta ku dhigto qalabka si aad u anfaca. Waxa jira nidaam “hal-furaha soo celinta” iyo shaqo beddelka luqadaha badan.

● Nidaamka conveyor Roller: waxay qabataa habka gudbinta wareegta, dhidibka rullaluistemadka iyo dhidibka workpiece ka samaysan xagal ah 18-21 digrii, miiska rullaluistemadka ee u dhexeeya jidhka foornada waxaa laga sameeyey 304 bir aan-magnetic ahama iyo biyo- la qaboojiyey, iyo workpiece si siman loo kululeeyey.

v Bedelka tamarta: kululaynta tan kasta oo bir ah ilaa 1050C, isticmaalka tamarta 310-330°C.