- 19

- Dec

Rebar okpomọkụ mmepụta akara

Rebar okpomọkụ mmepụta akara

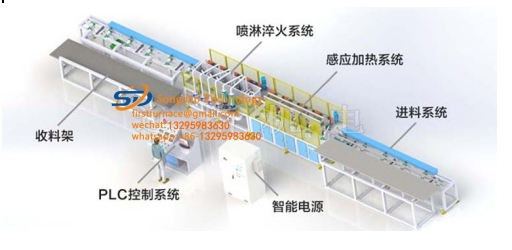

Ọpụrụiche na mmepụta nke ígwè okpomọkụ ọgwụgwọ mmepụta akara, ígwè okpomọkụ ọgwụgwọ mmepụta akara nwere àgwà nke obere ike oriri, obere mmetọ, elu mma, elu arụmọrụ, wdg The ígwè okpomọkụ ọgwụgwọ mmepụta akara bụ ike-azọpụta, green na ngwaahịa gburugburu ebe obibi. Nabata ndị ahịa ọhụrụ na ndị ochie ịkpọ anyị!

Akụkụ nke ahịrị mmepụta ihe na-ekpo ọkụ nchara nchara:

★ Iji PLC akpaka akara usoro ịchịkwa dum mmepụta akara, na-azọpụta ọrụ.

★ The ebu ala table nke ígwè mmanya quenching na tempering okpomọkụ ọgwụgwọ akụrụngwa adopts 304 na-abụghị magnetik igwe anaghị agba nchara. The axis nke roller table na-etolite otu akụkụ na workpiece. The workpiece na-agbagharị mgbe na-aga n’ihu na a edo ọsọ ka workpiece kwụsie ike.

★ The nri usoro adopts dị Nord ọsọ reducer na-achịkwa onwe ya ugboro Ntụgharị.

★Iji akpaaka mmanụ injection ụlọ maka moto na bearings. Nọgide na-enwe ndụ ọrụ nke components.

★ Akụkụ pneumatic nke sistemu ntinye na-agbaso ụdị ama ama dị ka cylinders, ibe abụọ, njikwa, wdg.

★ The fluctuation nso nke quenching na tempering okpomọkụ bụ ± 10 ℃. Kpoo ọkụ nke ọma.

★ The ígwè Ogwe mgbe quenching na tempering na ígwè mmanya okpomọkụ ọgwụgwọ mmepụta akara adịghị emepụta decarburization, ọ dịghị cracks, dịghị deformation, na ala ike oriri.

★ The ígwè mmanya mgbe quenching na tempering nwere elu siri ike na mmetụta ike.