- 19

- Dec

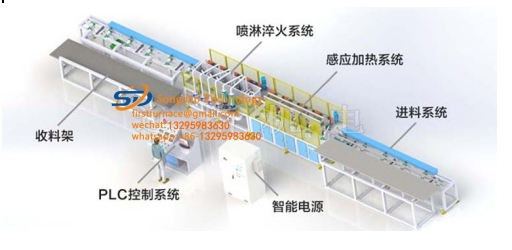

Rebar heat treatment production line

Rebar heat treatment production line

Specializing in the production of steel heat treatment production line, the steel heat treatment production line has the characteristics of low energy consumption, low pollution, high quality, high efficiency, etc. The steel heat treatment production line is an energy-saving, green and environmentally friendly product. Welcome new and old customers to call us!

Features of steel bar heat treatment production line:

★Using PLC automatic control system to control the whole production line, saving labor.

★The conveying roller table of the steel bar quenching and tempering heat treatment equipment adopts 304 non-magnetic stainless steel. The axis of the roller table forms an angle with the workpiece. The workpiece rotates while moving forward at a uniform speed to keep the workpiece stable.

★The feeding system adopts imported Nord speed reducer and is controlled by independent frequency converter.

★Using automatic oil injection facilities for motors and bearings. Maintain the service life of components.

★Pneumatic components of the input system adopt well-known brands such as cylinders, two-pieces, controllers, etc.

★The fluctuation range of quenching and tempering temperature is ±10℃. Heat evenly.

★The steel bars after quenching and tempering in the steel bar heat treatment production line do not produce decarburization, no cracks, no deformation, and low energy consumption.

★The steel bar after quenching and tempering has high toughness and impact strength.