- 22

- Aug

What are the types of induction hardening machine tools

Kedu ụdị nke induction hardening igwe ngwaọrụ

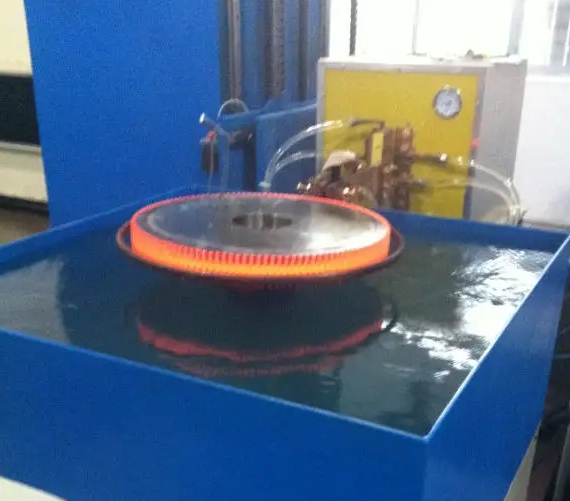

1. Outer circle quenching series: It is used to quench the outer surface of various shafts, rods, tubes and circular parts (such as bearings, valves, etc.) as a whole or locally.

2. Inner circle quenching series: quench the inner circle of various pipes and mechanical parts as a whole or partially, such as cylinder liners, shaft sleeves, etc.

3. End face and plane quenching series: perform overall or partial quenching on the end face and plane part of mechanical parts.

4. Pụrụ iche ekara akụkụ quenching usoro: ịrụ n’ozuzu ma ọ bụ ele mmadụ anya n’ihu quenching na a ụfọdụ elu nke pụrụ iche ekara akụkụ.

5. Extra large parts quenching series: perform overall or partial quenching on large and heavy parts, such as marine gears, dam sluice rails, large oil pipelines, etc.

6. Die elu quenching usoro: Die elu induction quenching igwe ngwá ọrụ bụ a CNC usoro ngwá adabara okpomọkụ ọgwụgwọ nke nnukwu ụgbọala cover ebu na nnukwu na-abụghị okirikiri ohere curved akụkụ.