- 17

- May

Kepiye carane nggawe induktor kanggo tungku pemanasan induksi?

Kepiye carane nggawe induktor kanggo tungku pemanasan induksi?

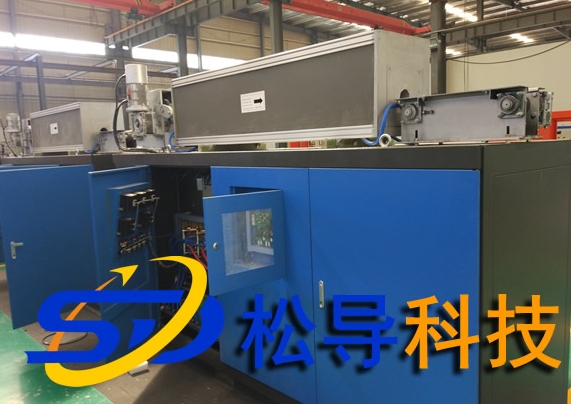

Induktor pemanas saka tungku dadi pemanasan is composed of a coil, a fixed frame, a water and electricity introduction system, a water-cooled feed rail, etc.

1) Koil induksi

The induction coil should be fired with a 99.9% pure oxygen-free copper rectangular thick-walled pipe, the pipe wall thickness is uniform, the water and electricity joints are sturdy and durable, and it is easy to disassemble.

2) Tabung tembaga sensor digawe saka tembaga abang T2, kanthi ukuran njaba 20mm * 30mm lan kekandelan tembok 3mm.

3) Desain Sensor:

The dielectric strength of the inductor is applied to the rated voltage plus 1000V without breakdown and flicker. The surface coating is silicone enamel 167, and the insulation resistance is not less than 0.5M when the rated voltage is below 1000V; when the rated voltage is above 1000V, not less than 1M. It is produced in strict accordance with the technological requirements of the sensor.

4) Lining induktor

Lumahing kumparan disemprotake karo lapisan resin insulasi kanthi kekuatan dhuwur, lan tembok njero, njaba njaba lan gulungan induksi dilapisi bahan tungku khusus (kalebu rolas bahan kayata korundum, kapasitor magnesia, lsp. kanthi refractoriness 1600 ° C), sing bisa ngluwihi induktor Umur layanan mesin bisa nyuda investasi pangopènan ing wektu salajengipun. Amarga mortir refractory nduweni tingkat insulasi lan insulasi panas sing dhuwur, mula nglindhungi koil induksi saka karusakan nalika lapisan njero rusak.

5) Paket sensor

Njaba sensor wis encapsulated karo 6mm Papan resin epoxy nglukis, lan materi pungkasan punika Papan asbes geni-tahan lan dipasang karo piring tembaga banyu-digawe adhem kanggo nyegah baris Magnetik saka pasukan ditarik.