- 18

- Dec

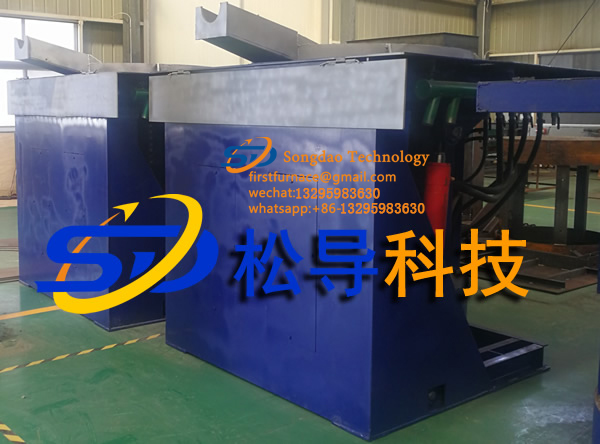

Proses perawatan panas saka tungku pemanasan induksi

Proses perawatan panas saka tungku pemanasan induksi

Cara proses kudu dioptimalake lan equipment performance must be mastered.

Nalika milih paramèter saben bagean kanthi bener, prioritas kudu diwenehi efisiensi lan linuwih. Pemanasan insulasi lan pendinginan, sirkulasi ora ora apik. Komposisi baja wis diganti, lan transformasi fase kudu dianggep. Nggunakake parameter modulasi sing diwilang, proses kasebut dipercaya lan luwih cocog.

It is more scientific to distinguish between steel and steel. The heating temperature is very important, and the insulation time should be sufficient. [–] High alloy steel should be divided into sections, and slow heating is guaranteed. Overheating and overheating are disadvantageous, only more weighing is required.

Insulation time should be considered, heating conditions and conditions. The number of parts and wall thickness, select calculation to grasp the focus. Various methods can be selected for oxidative decarburization control. Creating anaerobic is the key, the best option is vacuum.

Bagéan sing langsing lan vertikal karo akeh tembok lancip kanggo nyegah deformasi. Manungsa waé kudu dibayar kanggo owah-owahan dadakan saka salib-bagean, panas lan pangayoman cooling.

Cooling is greater than the critical value, and obtaining martensite is fundamental. The cooling control should be proper, proper cold and anti-cracking. To

Mesthekake atose dhasar lan langsung nesu kanggo ngilangi stres. Suhu disetel kanggo atose, lan baja beda-beda ing tempering beda. Kanggo

Tempering liyane ora bisa kurang, lan kinerja pangayoman dimensi stabil. Ing brittleness saka baja mbutuhake cooling cepet kanggo njamin kinerja memori.

Kinerja kekerasan duwe dhasar, lan hubungan kuantitatif bisa diowahi. Nguwasani proses ngelmu lan laku luwih mudhun-kanggo-bumi. Pengalaman akumulasi luwih ringkes, praktis, cepet lan dipercaya.