- 29

- Nov

The use effect of various mica insulating materials

The use effect of various mica insulating materials

Mica has strong insulation, heat resistance and mechanical ability, and is often used as an insulating material in electricians and electrical professions. It belongs to the aluminosilicate deposit, the lighter the color, the better the function. Muscovite is widely used, and biotite is less used due to its poor function. As an insulating material, mica can be divided into mica foil, mica tape and mica board.

Mica foil: It is very hard at room temperature, and becomes soft when heated. It is usually used in motors and electrical appliances as roll-to-roll insulation and rotor copper bar insulation.

Mica tape: It has good mechanical functions and is very soft at room temperature. It is often used to wrap motor coils for insulation. It can be divided into tung oil acid anhydride epoxy glass mica tape, epoxy boron ammonium glass powder mica tape, organic silicon flake mica tape and so on.

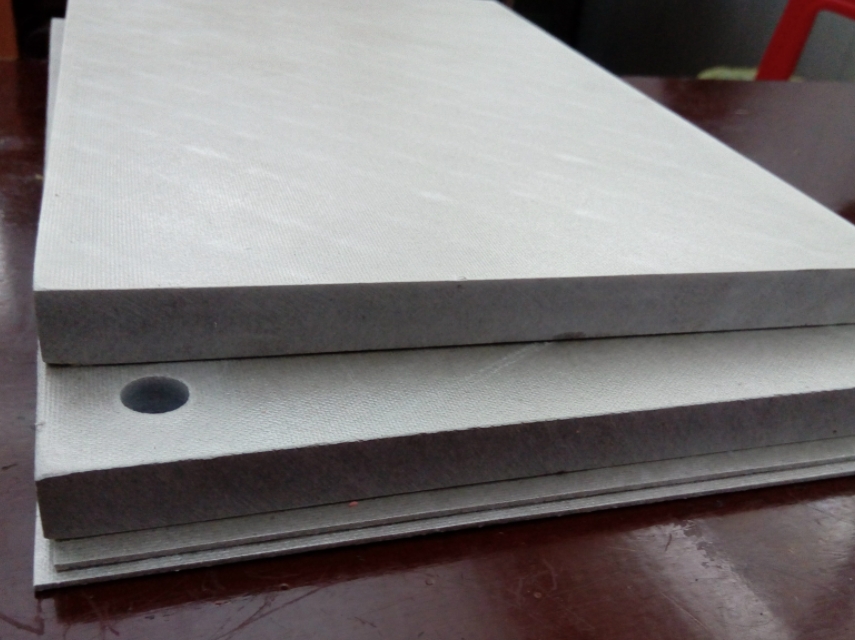

Mica board: It can be divided into commutator mica board, soft mica board, plastic mica board, cushion mica board and heat-resistant mica board. The commutator mica plate is resistant to wear, but because the raw material is phlogopite, the hardness is relatively small. The soft mica board is very flexible at room temperature and can be bent at will. Particular attention should be paid to temperature control during manufacturing. The molded mica board cannot be bent at room temperature, and becomes soft when heated, and the shape can be described as required. The strength of the padded mica board is exceptionally good, and it can withstand strong impact.

Among the three types of mica insulating materials, mica boards are used in large quantities and high temperature resistant mica boards, followed by mica tape, and finally mica foil. In large motors, mica is the only insulating material that can satisfy the application requirements, and its importance cannot be replaced by any other insulating material.