- 28

- Dec

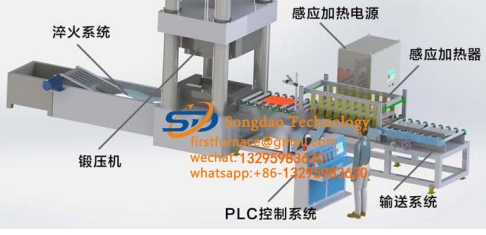

Steel plate quenching equipment

Steel plate quenching equipment

The steel plate and plate quenching production line is mainly composed of intermediate frequency power supply, induction induction system, quenching spray system, closed-loop temperature control system, input and output system, etc. The induction method is a main surface quenching method in the modern machine manufacturing industry. It has a series of advantages such as good quality, fast speed, less oxidation, low cost, good working conditions and easy realization of mechanization and automation.

Structural characteristics of steel plate quenching equipment:

(1) Steel plate quenching equipment inductor: a coil with a large inner diameter is wound with a pure copper tube. The copper pipe is wrapped with an insulating layer and is cooled by water during operation.

(2) Stepping mechanism: The sensor is fixed and the movable guide rail is made of heat-resistant stainless steel pipe, and it is cooled by water when it is working. The support frame is welded with section steel. The frequency advance mechanism adopts hydraulic transmission. One hydraulic cylinder makes the movable guide rail move up and down, and the other hydraulic cylinder causes the frequency advance mechanism to move forward by a material distance, which is controlled by the stroke limit switch interlock. Adjust the switch position to send blanks with a certain length range. The feeding cycle time is controlled by the time breaker, and the setting value can be changed to adjust the heating temperature and productivity of the blank.

(3) Furnace frame of steel plate quenching equipment: It is made by welding of model steel, and the sensor, stepping mechanism and operation control device are installed on it to form a whole.

(4) Warming power and cooling time; greatly improve the quality of heating products and heating repeatability, and simplify the operation technology of workers.

(5) The steel plate induction hardening furnace adopts intermediate frequency induction heating power control, full digital setting, touch screen operation mode, and high efficiency.