- 26

- Nov

Special heating furnace for making boron nitride

Special heating furnace for making boron nitride

1. Technical standards and parameters

1. Standards: equipment manufacturing is carried out in strict accordance with national standards and specifications

GB5959.3-88 “Veiligheid van elektrische verwarmingsapparatuur – Speciale vereisten voor inductie- en geleidende verwarmingsapparatuur en inductieapparatuur”

GB10066.3-88 “Basic Technical Conditions of Electric Heating Equipment-Induction Electric Heating Equipment”

GB10063.3-88 “Test Method for Electric Heating Equipment-Coreless Induction Furnace”

GB4086-85 “Technical Conditions of Electric Control Equipment for Intermediate Frequency Coreless Induction Heating”

JB/T4280-93 “Intermediate Frequency Coreless Induction Furnace”

JB/T8669-1997 “Semiconductor frequency conversion device for intermediate frequency induction heating”

GB/T14549-93 “Power Quality-Harmonics in Public Grid”

GB/T3924-1999 “Transformer for Intermediate Frequency Heating Device”

GB/DG2294-88 “Technische voorwaarden voor tussenfrequentie-spanningstransformatoren”

GB/DG2294-88 “Technical Conditions for Intermediate Frequency Current Transformers”

JB/T10358-2002 “Water cooling cable for industrial electric heating equipment”

2. technische parameters

| IF-voeding | Working form: Inverter parallel SCR 6-pulse power supply |

| Rectification form: 3-phase 6-pulse | |

| Uitgangsvermogen: 100KW | |

| Power efficiency ≥98% | |

| Startmodus: buffer variabele frequentie start | |

| Opstartpercentage: 100% (inclusief zware belasting) | |

| Rated frequency: 500HZ-1000HZ | |

| AC voltage: 400v | |

| DC-spanning: 500V | |

| Intermediate frequency voltage: 750v | |

| Maximum DC current: 200A | |

| AC current: 160A | |

| Ingangsfrequentie: 50Hz | |

| Dimensions: 1300mm×800mm×2000mm (length×width×height) | |

| Gewicht: ongeveer 1000KG | |

| sensor | Minimum power factor: 0.90. There is no power factor meter on the detection standard IF cabinet, and the DC voltage reaches the maximum 500v power factor that is above 0.9. Because the intermediate frequency power supply purchased by Party A is regulated by voltage and power, power reduction is accomplished by reducing the DC voltage. Reduce the power, the power factor should also be reduced. |

| Working method: one electric and two furnaces | |

| Working temperature: 2300℃, quick connector for water inlet and outlet | |

| Induction coil specification: outer diameter 980mm height: 1020mm, copper tube: loose guide reasonable calculation of design coil number and specifications | |

| Weight: about 200KG induction coil base welded with 120mm channel steel, convenient for forklift use |

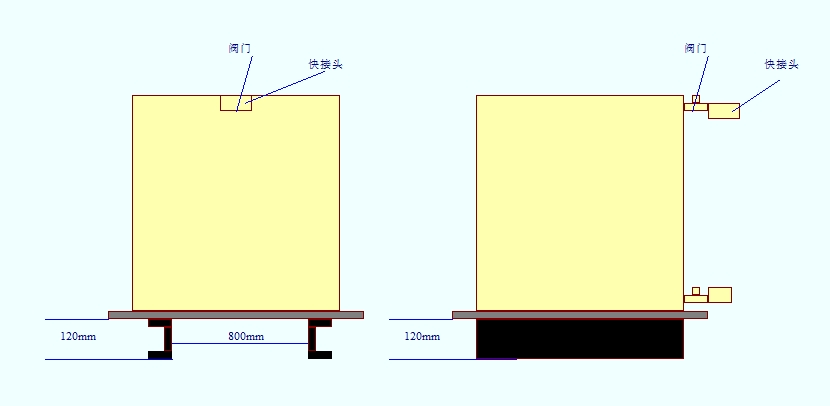

Base channel steel outline drawing