- 20

- Nov

Refractory materials for cupola

Refractory materials for cupola

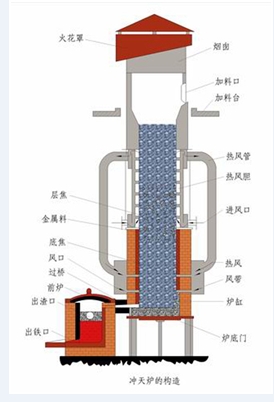

The cupola is an iron-making furnace or a stir-frying furnace, and its main function is to make iron. The working temperature is 1400~1600℃. The furnace body is divided into furnace bottom, furnace body, forehearth and bridge.

The bottom of the cupola is in direct contact with the hot molten iron and bears the weight of all the charge. ASC ramming material or carbon ramming material should be used in this part to help improve the life of the cupola bottom.

The upper working layer of the furnace body is mechanically impacted and worn during charging. It is built with fan-shaped hollow iron bricks, and the outer side is made of quartz sand.

The working layer of the lower part of the furnace body, the coke combustion zone at the tuyere and above are very high in temperature, and are also subject to slag erosion, airflow erosion and abrasion. Here, corrosion-resistant magnesia chrome bricks or magnesia bricks are used.

The oxidizing atmosphere of the lower working layer of the furnace body is weakened, and ASC ramming material is used. The other parts of the furnace body are low in temperature, so clay bricks or semi-silica bricks are used. The permanent layer or insulation layer of the furnace body is made of clay light-weight insulation bricks.

Use clay bricks or high-alumina bricks for the forehearth and bridge parts of the cupola, and use ASC ramming material for the part in contact with molten iron; use ASC ramming material with higher silicon carbide content, prefabricated parts or refractory bricks for the part that contacts the slag; Use clay bricks or lightweight clay bricks for insulation or permanent layers.

In general, the bottom of the furnace uses carbon ramming materials, clay bricks, and ASC ramming materials, the middle of the furnace body uses magnesia chrome bricks, magnesia bricks, corundum bricks, and clay bricks, the top of the furnace body uses hollow iron bricks, and the lower part of the furnace body Clay bricks, ASC bricks, ASC ramming materials, ASC preforms, ASC preforms for the slag outlet, ASC ramming materials, and ASC quality gun mud and ASC preforms for the iron outlet.

Clay bricks for forehearths, bridges, permanent layers, ASC bricks, light-weight insulating clay bricks for permanent layers or insulation layers.