- 20

- May

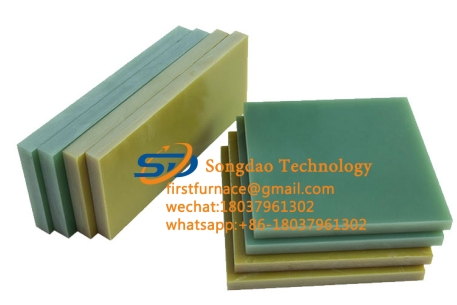

Kodi magawo a epoxy resin board ndi ati

What are the parameters of epoxy resin board

Kuti mukwaniritse bwino kugwiritsa ntchito bolodi la epoxy resin, magawo ena amafunikira. M’munsimu, opanga akatswiri adzatifotokozera mwatsatanetsatane. Bwerani mudzaphunzire zambiri za izo.

Parameter classification of epoxy resin sheet: dielectric constant parameter, dielectric loss parameter, TG value parameter

Epoxy resin sheet is a double-sided copper-clad PCB sheet made of epoxy resin + glass cloth. The commonly used FR4 copper-clad sheet has a relative dielectric constant of 4.2-4.7. This dielectric constant will change with temperature. In the temperature range of 0-70 degrees, the maximum change range can reach 20%. A change in the dielectric constant will cause a 10% change in the line delay, and the higher the temperature, the greater the delay. The dielectric constant will also change with the signal frequency. The higher the frequency, the smaller the dielectric constant. In general, the classic value of the dielectric constant is 4.4. The dielectric constant changes with frequency as shown in Fig.

The dielectric constant (Dk, ε, Er) determines the speed at which electrical signals travel in the medium. The speed at which electrical signals travel is inversely proportional to the square root of the dielectric constant. The lower the dielectric constant, the faster the signal transmission. Let’s make a visual analogy. It’s like you are running on the beach, and the depth of water submerges your ankles. The viscosity of water is the dielectric constant. The more viscous the water, the higher the dielectric constant, and the slower you run.

The dielectric constant is not very simple to measure or define. It is not only related to the characteristics of the medium itself, but also to the test method, test frequency, and the state of the material before and during the test. The dielectric constant will also change with the change of temperature. Some special materials take into account the temperature factor in the development. Humidity is also an important factor affecting the dielectric constant, because the dielectric constant of water is 70, and there is very little moisture. , will cause significant changes.

Kutayika kwa dielectric kwa pepala la epoxy resin: kutayika kwa mphamvu mkati mwa zinthu zotsekereza chifukwa cha hysteresis ya dielectric conductance ndi dielectric polarization pansi pa mphamvu yamagetsi. Zomwe zimatchedwanso dielectric loss, zomwe zimatchedwa dielectric loss. Pansi pa mphamvu ya gawo lamagetsi losinthasintha, mbali yowonjezera δ ya angle yophatikizidwa (mphamvu factor angle Φ) pakati pa phasor yamakono ndi phasor yamagetsi yomwe ikuyenda mu dielectric imatchedwa dielectric loss angle. Kutayika kwa dielectric kwa pepala la epoxy resin nthawi zambiri kumakhala 0.02, ndipo kutayika kwa dielectric kumawonjezeka ndi kuchuluka kwafupipafupi.

TG mtengo wa epoxy utomoni pepala: amatchedwanso galasi kusintha kutentha, zambiri 130 ℃, 140 ℃, 150 ℃, 170 ℃.