- 01

- Nov

Harmonic control scheme for induction melting furnace

Harmonic control scheme for induction melting furnace

Induction melting furnace: is a power supply device that converts 50HZ power frequency alternating current into intermediate frequency (300HZ above to 1000HZ), which converts three-phase power frequency alternating current into direct current after rectification, and then converts the direct current into adjustable intermediate frequency current for supply The medium frequency alternating current flowing through the capacitor and the induction coil generates high-density magnetic lines of force in the induction coil, and cuts the metal material contained in the induction coil, which generates a large eddy current in the metal material.

1. Working principle of induction melting furnace

The induction melting furnace is mainly composed of a power supply, an induction coil and a crucible made of refractory materials in the induction coil. The crucible contains metal charge, which is equivalent to the secondary winding of the transformer. When the induction coil is connected to the AC power supply, an alternating magnetic field is generated in the induction coil. Since the charge itself forms a closed loop, the secondary winding is characterized by only one turn and is closed. Therefore, induced current is generated in the charge at the same time, and when the induced current passes through the charge, the charge is heated to promote its melting.

The induction melting furnace uses an intermediate frequency power supply to establish an intermediate frequency magnetic field, which generates induced eddy currents inside the ferromagnetic material and generates heat, so as to achieve the purpose of heating the material. The induction melting furnace uses a 200-2500Hz intermediate frequency power supply for induction heating, melting and heat preservation. The induction melting furnace is mainly used for melting carbon steel, alloy steel, special steel, and can also be used for melting and heating of non-ferrous metals such as copper and aluminum. The equipment is small in size. , Light weight, high efficiency, low power consumption, fast melting and heating, easy control of furnace temperature, and high production efficiency.

2. Harmonic characteristics generated by induction melting furnace

Generally, 6-pulse induction melting furnaces mainly produce 5th and 7th characteristic harmonics; for 12-pulse converter devices, they mainly produce 5th, 11th, and 13th characteristic harmonics. Under normal circumstances, small converter devices use 6 pulses, and larger ones use 12 pulses. For example, the double secondary side of the furnace transformer is connected in Y/△ type to achieve a phase shift of 30 degrees; or the high voltage side of the two furnace transformers adopts extension triangle or zigzag Phase-shifting measures such as type connection and secondary double-secondary star-corner connection form a 24-pulse intermediate frequency power supply to reduce the degree of harmonics’ influence on the power grid.

Three, harmonic hazards

The induction melting furnace generates a large number of harmonics when in use, which causes serious harmonic pollution in the power grid. Harmonics reduce the efficiency of electric energy transmission and utilization, cause electrical equipment to overheat, generate vibration and noise, and make its insulation aging, reduce service life, and even malfunction or burn; harmonics can cause local parallel resonance or series resonance in the power system. Amplify the harmonic content, causing the capacitor compensation equipment and other equipment to burn out. In the case where reactive power compensation cannot be used, reactive power fines will occur, resulting in an increase in electricity bills. Harmonics can also cause malfunctions of relay protection and automatic devices, causing confusion in electric energy measurement. For the outside of the power system, harmonics will cause serious interference to communication equipment and electronic equipment. Therefore, improving the power quality of induction melting furnaces has become the main focus of response.

Four, induction melting furnace harmonic control

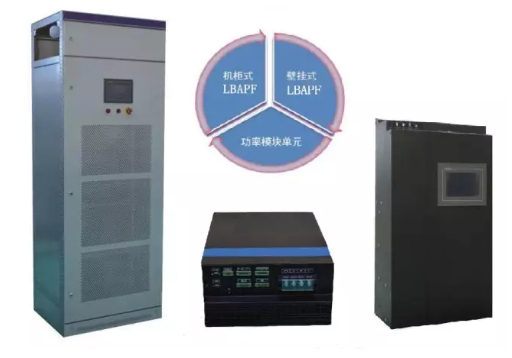

LBAPF-ZP series of special active filters for intermediate frequency equipment are especially suitable for induction melting furnace load systems with very high harmonic content. It can solve the heating and heating of the system where the load is located, the increase in noise, the failure of capacitor compensation switching, and the circuit components Damages and malfunctions caused by excessive harmonic currents such as damage.

The LBAPF-ZP series of special active filters for intermediate frequency equipment are installed behind the reactive power compensation and at the front of the load. The harmonic filtering rate for the rear load is as high as 90%.