- 28

- Apr

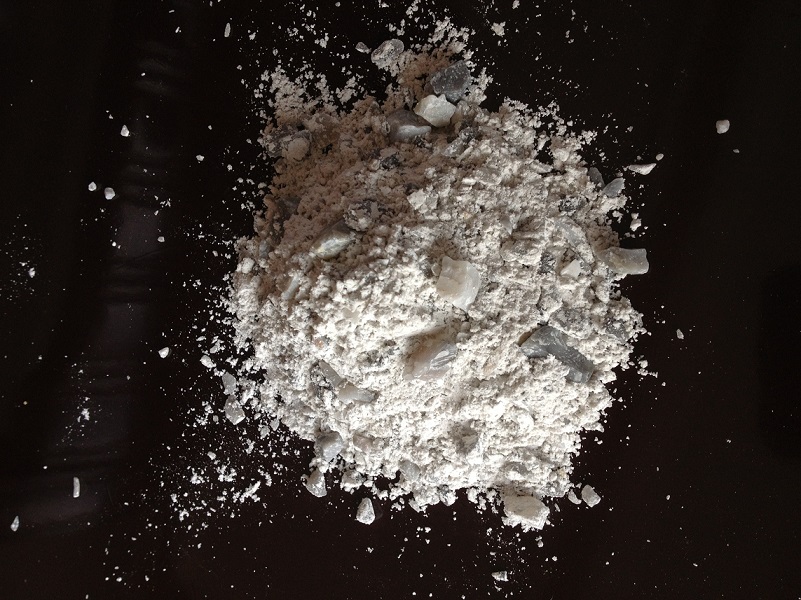

Quartz jecha musanganiswa

Quartz jecha musanganiswa

1. Muchidimbu chigadzirwa

Ichi chigadzirwa chigadziko chevira, chakakodzera kushandiswa mumiti yesimbi uye nheyo dzepakati frequency magetsi emagetsi. Chigadzirwa chacho ndeye quartz-based refractory material, zvinhu zvine acidic, zvichibva pa-high-purity microcrystalline quartz matrix uye yakawedzera chikamu chefused silica, high-temperature resistant binder, anti-surge stabilizer, anti-seepage agent, anti-cracking. mumiririri, uye kunze kwenyika inoumbwa micro-upfu zvinhu , Kuwedzera kusakosha kwembambo yechoto kunovandudzwa zviri pachena, uye hapana kutsemuka kana choto chatonhodzwa.

Iyo inoratidzirwa nekuchena kwepamusoro kwezvinhu zvakasvibirira, inonzwisisika zvinhu ratio, yakakwidziridzwa inopisa simbi corrosion resistance, yakasimba kuramba kutonhora kwakanyanya uye kupisa kwakanyanya, kupfava kwakanyanya, kusimba kupikisa, kupfavisa tembiricha yakanyanya, kupisa kwakanyanya kwesimba rekumanikidza, tembiricha yakanyanya flexural. simba Yakakwirira, yakanaka slag kuramba, kunyanya yakakodzera kupindirana kwekushanda kwehombe-yepakati frequency induction furnace.

2. Zvimiro zvinoenderana (kemikari yakagadzirwa haina sintering agent)

SiO2 ≥ 98.5% CaO+MgO ≤0.1% Fe2O3 ≤ 0.2%

Material density: 2.1g/cm3 High tembiricha kuramba: 1780 ℃

3. Kuvaka choto, ovheni uye sintering process

Iyo chaiyo yekuvakira choto chivakwa, ovheni uye sintering process ndiyo kiyi yekuve nechokwadi chekushanda kwakajairwa kwebindu rechoto. Usati wavaka choto nechoto, zvinokurudzirwa kutarisa kune “Furnace Building uye Sintering Process Instructions” yakapiwa nekambani yedu.

4. Packaging uye kuchengetedza nzira

Multi-layer hunyoro-uchapupu bepa kurongedza 25kg / bhegi, inogona kuiswa mumatani mabhegi, 106cmX106cm pallets uye yakasimba yakatambanudzwa firimu zvinoenderana nezvinodiwa nevatengi. Chengeta panzvimbo yakaoma kudzivirira kubatwa kwemwando. Nguva yekuchengetedza haisi kupfuura gore rimwe.