- 28

- Apr

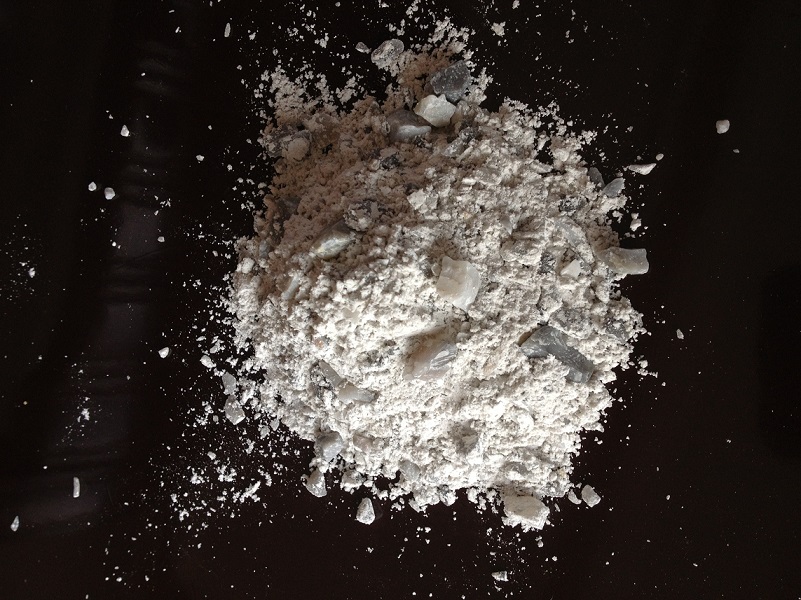

Quartz sand mixture

Quartz sand mixture

1. Product brief

This product is a furnace lining material, suitable for use in steel plants and foundries for medium frequency electric furnaces. The product is a quartz-based refractory material, the material is acidic, based on the high-purity microcrystalline quartz matrix and added part of fused silica, high-temperature resistant binder, anti-surge stabilizer, anti-seepage agent, anti-cracking agent, and imported composite micro-powder material , The expansion disadvantage of the furnace lining is obviously improved, and there is no crack when the furnace is cooled.

It is characterized by high purity of raw materials, reasonable material ratio, enhanced hot metal corrosion resistance, strong resistance to extreme cold and extreme heat, high softness, strong impact resistance, high load softening temperature, high high temperature compressive strength, high temperature flexural strength High, good slag resistance, especially suitable for intermittent operation of large-scale intermediate frequency induction furnace.

2. Related parameters (chemical composition does not contain sintering agent)

SiO2 ≥ 98.5% CaO+MgO ≤0.1% Fe2O3 ≤ 0.2%

Material density: 2.1g/cm3 High temperature resistance: 1780℃

3. Furnace building, oven and sintering process

The correct furnace building, oven and sintering process is the key to ensure the normal operation of the furnace lining. Before building the furnace and the furnace, it is recommended to refer to the “Furnace Building and Sintering Process Instructions” provided by our company.

4. Packaging and storage methods

Multi-layer moisture-proof paper packaging 25kg/bag, can be packaged in ton bags, 106cmX106cm pallets and strong stretch film according to customer requirements. Store in a dry place to prevent moisture absorption. The storage period is no more than one year.