- 10

- Sep

High-efficiency, energy-saving and environmentally friendly heat conduction oil induction heating equipment

High-efficiency, energy-saving and environmentally friendly heat conduction oil induction heating equipment

The high-efficiency, energy-saving and environmentally friendly heat transfer oil pajisjet e ngrohjes me induksion adopts DSP intelligent two-in-one machine, and the host part integrates the DCS (distributed control system) field control function. The host can be placed in the central control room. The LCD screen of the equipment has all operating functions. This LCD screen can be used as a heating device operating station, or it can communicate with the device LCD screen through configuration software to obtain relevant parameters or control function permissions, or use analog control for remote control.

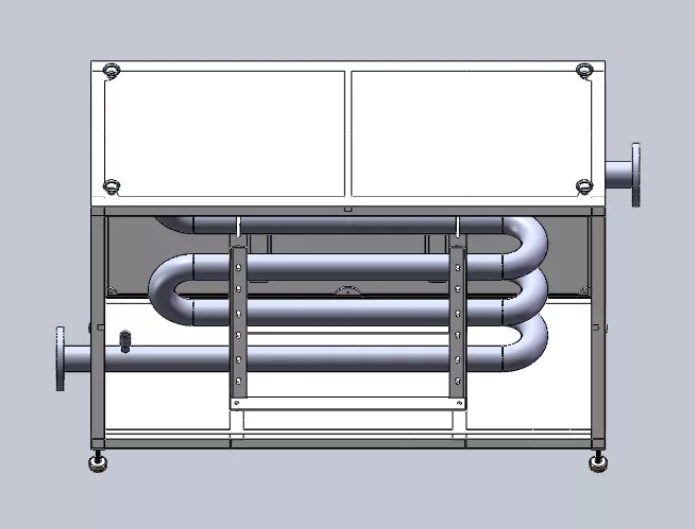

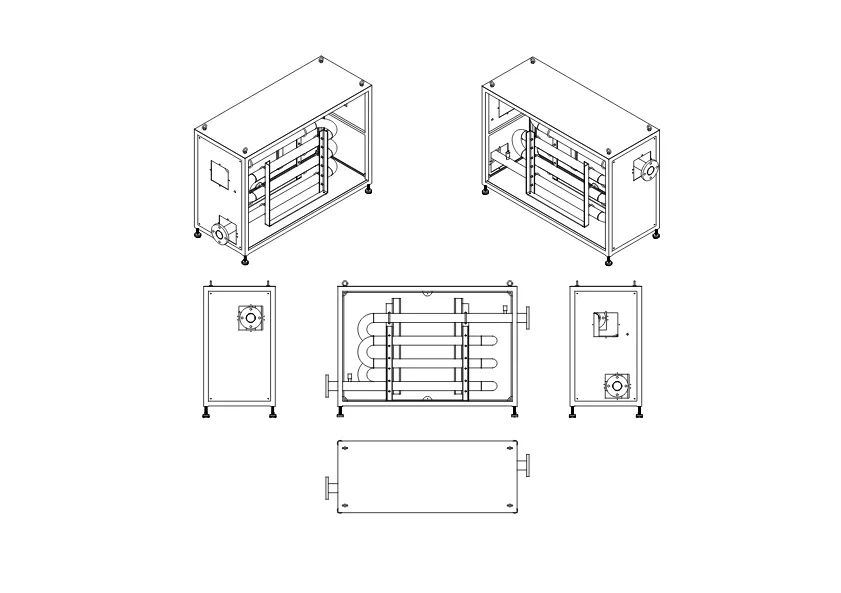

Heat conduction oil heating process design: design and manufacture 2-position induction heating power supply. Two 120KW air-cooled induction heating power supplies are used to heat the heat transfer oil pipes. The heating area can be controlled in different areas. The heating temperature can be controlled by thermocouples to achieve rapid heating of the heat transfer oil and closed-loop temperature control of the heat transfer oil. There are 2 sets of coil heating devices and 4-point temperature control devices in the heating zone of this section. When only one set of reactor is needed to work, one set of heating equipment can be controlled by DCS to stop heating. When two sets of reactors are needed to work, you can Turn on the two sets of induction heating equipment at the same time to prevent the heat exchange area of one set of coil heating device from being insufficient, causing the heat transfer oil temperature to drop too fast when the heating is urgently needed, causing abnormal conditions. The temperature measurement system of the heat conduction oil device adopts a control method in which thermocouples are arranged at the inlet and outlet, which facilitates the closed-loop control of the oil temperature by induction heating.

Advantages of thermal oil induction heating transformation:

1. High-efficiency and energy-saving, high-speed thermal efficiency is more than 95%, and it can save electricity by more than 30% compared with electric heating rod heating method under equal conditions.

2. The preheating time is short, which is 2/3 shorter than the heating by the electric heating rod.

3. Blocking heating, the up-frequency heating cable is only heated, and it is safe to block the heat transfer oil. Prevent the heating rod from leaking electricity and cause fire.

4. Reduce the use and protection cost, the heating cable is not damaged, to prevent frequent replacement of the heating rod, so as to avoid the high temperature of the heating rod.

5. The circuit uses our company’s fourth-generation DSP digital intelligent induction heating equipment, the temperature can be accurately controlled, and the German IGBT module is selected, the circuit is leading, stable and reliable.

6. Improve the working environment, less heat dissipation, and the outer surface of the heating cylinder is almost room temperature.

7. Accurate temperature control, temperature difference ≤±1 C, high temperature heating can be completed. It can be heated to 40°C to 60°C under the condition that the heat transfer oil permits. Adapt to user requirements.

8. The induction heating equipment and heating cables adopt a fully air-cooled structure, which is safe, energy-saving, environmentally friendly and reliable.