- 23

- May

The cooling tower cooling principle of induction melting furnace

The cooling tower cooling principle of индукционе пећи за топљење

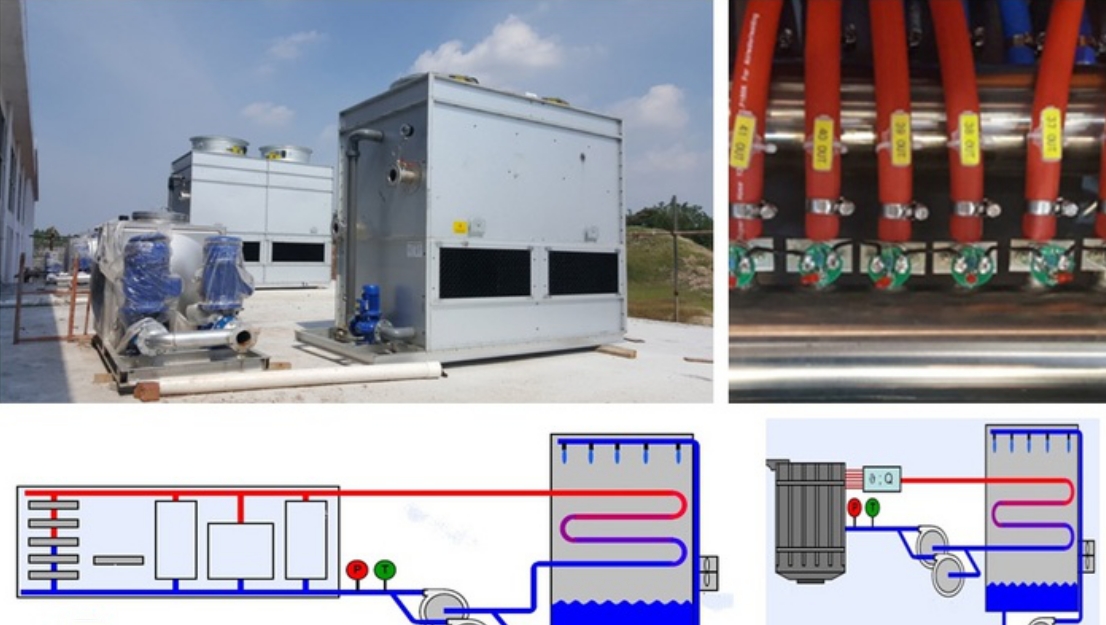

In the production of induction melting furnace, the induction melting furnace must be cooled. At present, the more commonly used cooling method of induction melting furnace is closed cooling tower cooling. However, in the technical exchange of induction melting furnace, many customers are not clear about the cooling principle of the cooling tower of the induction melting furnace. Let me explain it to you.

The cooling of the cooling tower of the induction melting furnace is actually a heat dissipation device, so that the medium that needs to be cooled is cooled by the evaporation and heat dissipation of water in the tower. In order to make full use of water resources, reduce the load on the urban tap water supply pipe network, and at the same time reduce operating costs, the cooling water used for the induction melting furnace refrigeration is treated by cooling towers and recycled. The cooling tower of the induction melting furnace uses natural ventilation or mechanical ventilation to cool the sprayed hot water.

In the production of induction melting furnaces, cooling towers are widely used. The water in the cooling tower is evenly sprayed on the cooler by the spray nozzle, and the cooling medium exchanges heat with the water as it flows through the cooler. In this process, the medium is cooled, and the water on the surface of the cooler absorbs temperature and flows to the packing layer. , A uniform water film is formed on the surface of the filler, so that the contact surface between water and air is enlarged, the contact time is prolonged, and the water and air conduct sufficient heat exchange.

There are two ways of air flow. One is to distribute the air evenly by the air inlet shutters of the cooling tower, and the natural suction generated by the air duct draws the air from bottom to top; the other method is to install a fan to make the air flow. Namely natural ventilation and mechanical ventilation. After the air is heated by the medium and water, the temperature rises and the water content increases, and it is discharged into the atmosphere when it rises to the top of the tower close to the saturated state. At this time, the medium in the cooling tower of the induction melting furnace has been cooled down. After the water passes through the filler layer and the air, the water temperature drops. The cooled water falls into the bottom water pan and is recirculated to the water distribution system by the water pump. Sprinkle on the cooler, so the cooling cycle is carried out.

The above is the principle of cooling tower cooling of induction melting furnace, are you clear about it?