- 06

- Sep

Molamu o hulang khalase ea fiber ea epoxy

Molamu o hulang khalase ea fiber ea epoxy

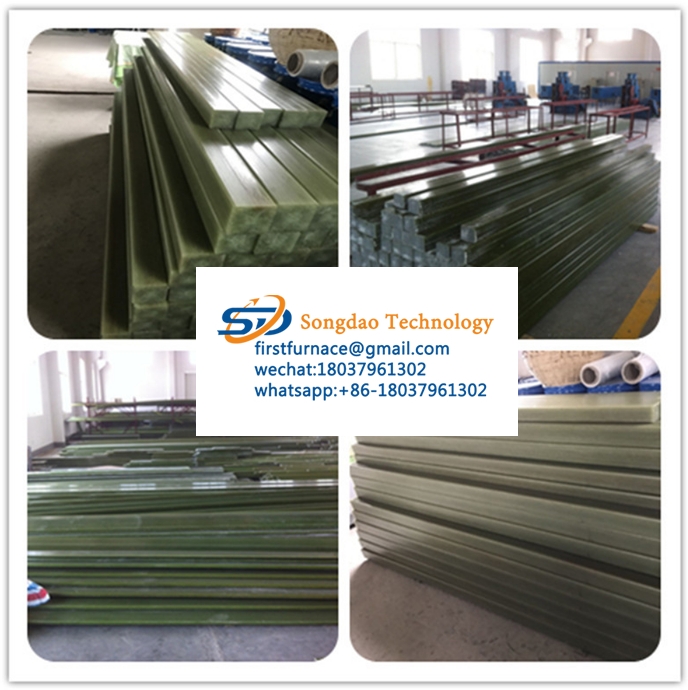

Molamu oa ho taka oa khalase ea epoxy e entsoe ka khalase ea khalase e kentsoeng ka epoxy resin matrix ka pultrusion e phahameng ea mocheso. Sehlahisoa se na le: boima bo bobebe, thepa e tsitsitseng ea mochini, thepa e ntle haholo ea ho koala, ‘me e ka koahela bophahamo ba matla a 10kV-1000kV. Ts’ebetso ea ts’ebetso ea sehlahisoa e ikhethile ka ho khetheha, ka matla a eona a matla a ho fihla 1360Mpa kapa kaholimo

Kenyelletso ea sehlahisoa

Molamu o hulang khalase ea fiber ea epoxy e entsoe ka fiber e matla ea aramid le fiber e khabisitsoeng ka “epoxy resin matrix” kamora pultrusion e phahameng ea mocheso. E na le litšobotsi tsa matla a bartolomeo phahameng, babatsehang qhoaele hanyetsa, acid e le ho hanyetsa a alkali, ho hanyetsa ts’enyeho le tse ling tse babatsehang phahameng ho hanyetsa mocheso. Lihlahisoa li loketse limela tsa aluminium tsa electrolytic, limela tsa tšepe, lisebelisoa tsa metallurgic tse phahameng, lisebelisoa tsa motlakase tse phahameng haholo, masimo a sepakapaka, li-transformer, li-capacitor, li-switch, li-switch tsa voltage e phahameng le lisebelisoa tse ling tsa motlakase o phahameng.

Ts’ebetso ea sehlahisoa

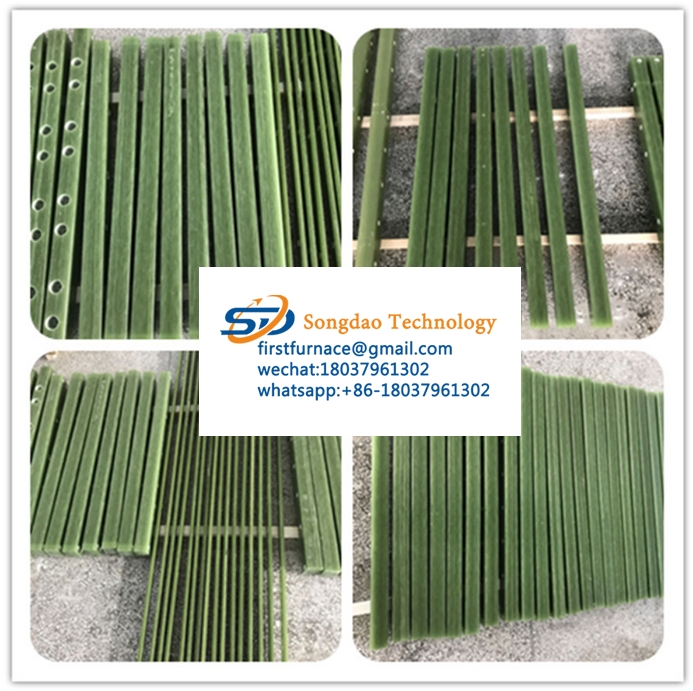

1. Ka lebaka la pultrusion e tsoelang pele ea fiber ea aramid le fiber ea khalase, sehlahisoa se na le khanyetso e ntle ea khatello ea mochini le khatello ea mochini. Matla a eona a tensile a fihla ho 1500MPa, e fetang hōle index ea 570Mpa ea No. 45 e entsoeng ka tšepe e nepahetseng. Ts’ebetso e ntle ea motlakase, mamella palo ea matla a 10kV-1000kV. Matla ts’enyeho hanyetsa, phahameng ba kobang matla, ha ho bonolo ho koba, ho le bonolo ho sebelisa joalo joalo.

2. Mocheso o sebetsang oa nako e telele oa sehlahisoa ke 170-210 ℃; Mocheso o phahameng oa ts’ebetso oa sehlahisoa ke 260 ℃ (ka tlase ho metsotsoana e 5).

3. Ka lebaka la ts’ebeliso ea moemeli oa boleng bo holimo, bokaholimo ba sehlahisoa bo netefalitsoe hore bo boreleli haholo, bo se na phapang ea mebala, bo se na li-burrs, ebile bo sena mengoapo.

4. Sekhahla sa ho hanyetsa mocheso le sekhahla sa sehlahisoa se fihlella H grade.

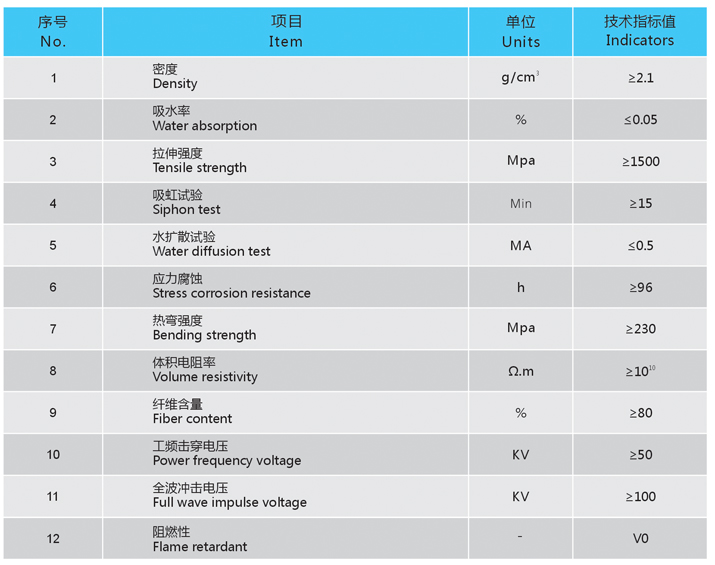

C. Lihlahisoa tsa tekheniki ea sehlahisoa

- Litlhaloso tse teng tsa hlobo

Insulation tafole lisekoere ga tlhaloso tafole

| Square molamu ga tlhaloso tafole | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso |

| 6 * 30 | 20 * 20 | 30 * 30 | 32 * 42 | 40 * 40 | 50 * 50 | 60 * 60 | 70 * 80 | |

| 8 * 30 | 20 * 30 | 30 * 40 | 34 * 54 | 40 * 50 | 50 * 60 | 60 * 70 | 80 * 90 | |

| 10 * 20 | 20 * 35 | 30 * 50 | 35 * 50 | 40 * 60 | 50 * 70 | 60 * 100 | ||

| 10 * 30 | 20 * 40 | 30 * 120 | 35 * 160 | 40 * 95 | 50 * 80 | 60 * 120 | ||

| 12 * 30 | 20 * 50 | 30 * 150 | 35 * 200 | |||||

| 15 * 30 | 20 * 80 | 30 * 140, T mofuta) | ||||||

| 15 * 150 | 20 * 200 | |||||||

| 18 * 30 | ||||||||

| E ka khaoloa ka ho rata ho latela litlhoko tsa bareki. | ||||||||

Ga tlhaloso tafole ea insulated chitja

| potoloha molamu ga tlhaloso tafole | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso | ga tlhaloso |

| Φ10 | EA-20-TK | EA-30-TK | EA-40-TK | EA-50-TK | Φ60 | EA-70-TK | |

| 12 | EA-22-TK | Φ32 | 中 42 | EA-53-TK | EA-63-TK | 80 | |

| 16 | EA-24-TK | Φ34 | EA-45-TK | EA-55-TK | 90 | ||

| Φ17 | EA-25-TK | Φ35 | EA-46-TK | EA-56-TK | 100 | ||

| Φ17.2 | EA-26-TK | Φ36 | |||||

| EA-18-TK | EA-28-TK | <P38 | |||||

| EA-39-TK | |||||||

| Bolelele bo ka khaoloa ka boithatelo ho latela litlhoko tsa bareki. | Bolelele bo ka khaoloa ka boithatelo ho latela litlhoko tsa bareki. | ||||||

Hexagonal li sireletsang serameng molamu ga tlhaloso tafole

| Hexagonal bareng | ga tlhaloso | ga tlhaloso | ga tlhaloso |

| Lehlakoreng le fapaneng | Lehlakoreng le fapaneng | Lehlakoreng le fapaneng |

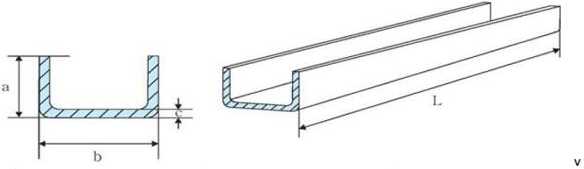

Tlhaloso ea tafole ea mofuta oa C

| (bolelele) | b (bophara) | c (botenya) | L (bolelele) |

| 50 | 74 | 10 | E ka khaoloa ha e batloa |

| 80 | 100 | 16 | E ka khaoloa ha e batloa |

| 120 | 100 | 10 | E ka khaoloa ha e batloa |

| 27 | 50 | 10 | E ka khaoloa ha e batloa |