- 11

- Jan

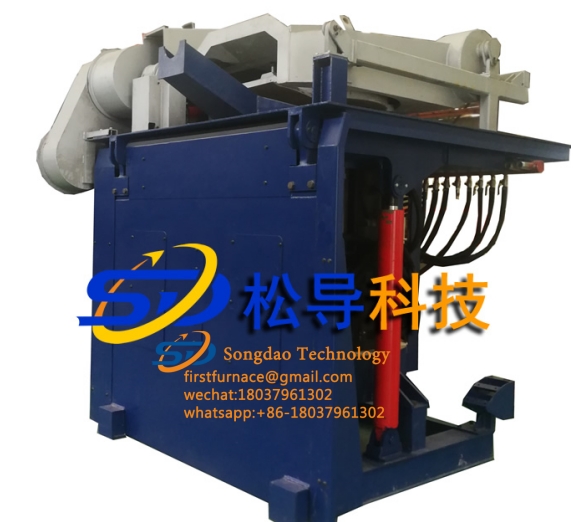

Induction melting furnace produces castings with stable mechanical strength

Induction melting furnace produces castings with stable mechanical strength

In the induction melting furnace, cast iron of various compositions can be melted. Due to the low oxidation loss during the melting process, the composition and temperature of the molten iron can be adjusted more conveniently, and the quality of the obtained molten iron is relatively stable. Under normal circumstances, using an induksi tungku lebur instead of a cupola to melt cast iron can often reduce the rejection rate of castings by 1/2 to 2/3, which will bring higher economic benefits to the enterprise. The gas content (nitrogen, hydrogen, oxygen) of cast iron obtained by induction melting furnace is 1/3 to 1/4 less than that of cupola melting castings, with less non-metallic inclusions, high casting strength and reliable performance. Under normal circumstances, the cross-sectional area of castings can be reduced, and the consumption of metal materials can be reduced by 20% to 25%. Save metal raw materials and reduce the weight of machinery and equipment

https://songdaokeji.cn/category/products/induction-melting-furnace

https://songdaokeji.cn/category/blog/induction-melting-furnace-related-information

Telepon: 8618037961302