- 10

- May

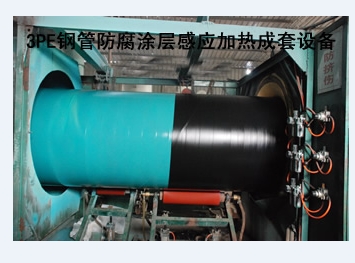

How to choose steel pipe anti-corrosion heating equipment?

How to choose steel pipe anti-corrosion heating equipment?

● Power supply system: 200KW-6000KW, the hourly output is 0.2-16 tons.

● Induction heating system: Customized design of inductors according to your needs, induction furnace body of workpiece size, shape and size, temperature controllable furnace body, energy saving, high efficiency and fast speed.

● Material storage system: The thick-walled square tube is welded to form a material storage platform, with an inclination of 13 degrees, which can store more than 20 pieces of material.

● Temperature control system: Infrared temperature measurement PLC temperature closed-loop automatic temperature control system.

● PLC control: specially customized man-machine interface, highly user-friendly operation instructions, remote operation console of industrial computer system with touch screen, all-digital high-depth adjustable parameters, make you control equipment more handy. There is a “one-key restore” system and multiple language switching functions.

● Roller conveying system: It adopts a rotating conveying mechanism, the axis of the roller and the axis of the workpiece form an angle of 18-21 degrees, and the roller between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled, and the workpiece is heated evenly.

▲ Energy conversion: heating each ton of steel to 1050℃, the power consumption is 310-330 degrees.